Page 3 of 6

Posted: 19 Jul 2007, 08:11

by Kostas

Posted: 19 Jul 2007, 08:24

by Kostas

Posted: 19 Jul 2007, 08:32

by Kostas

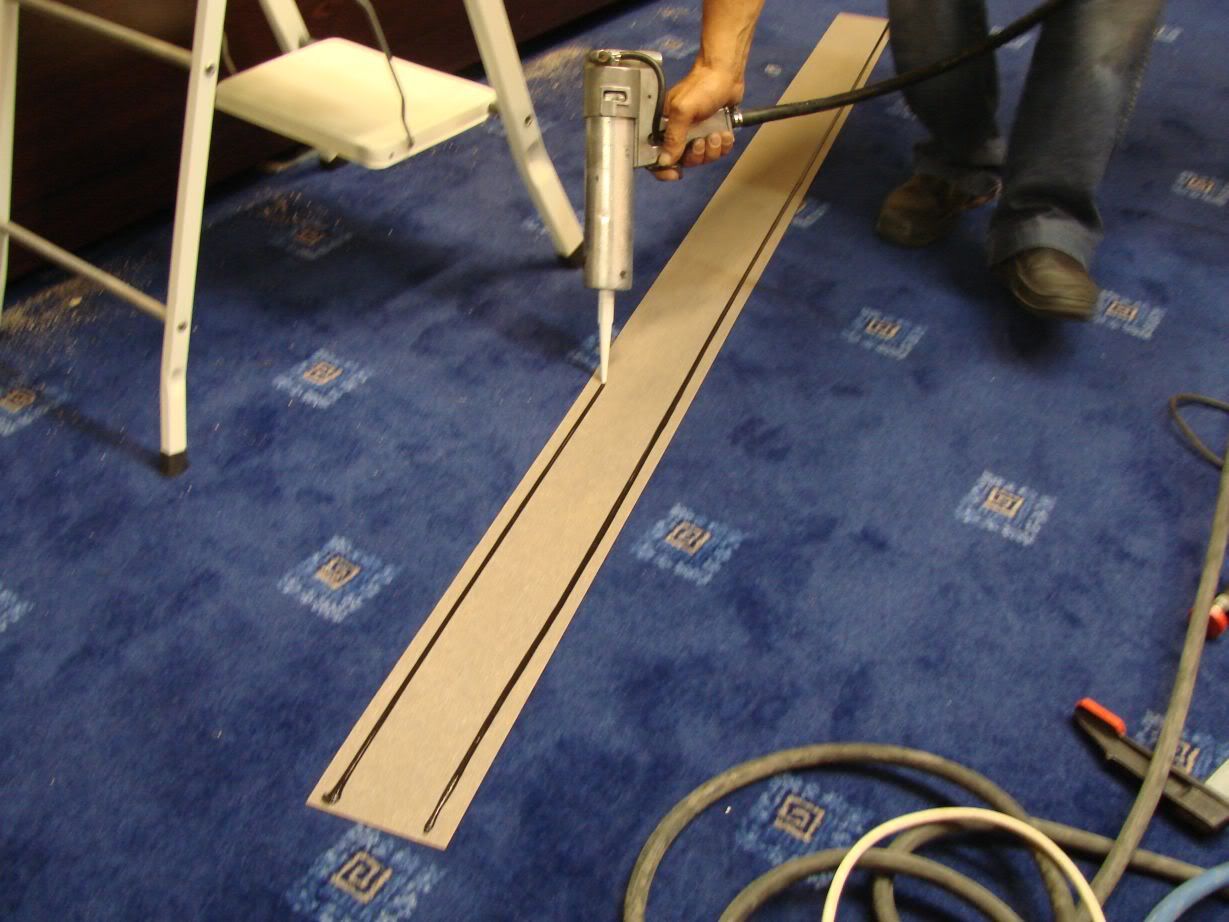

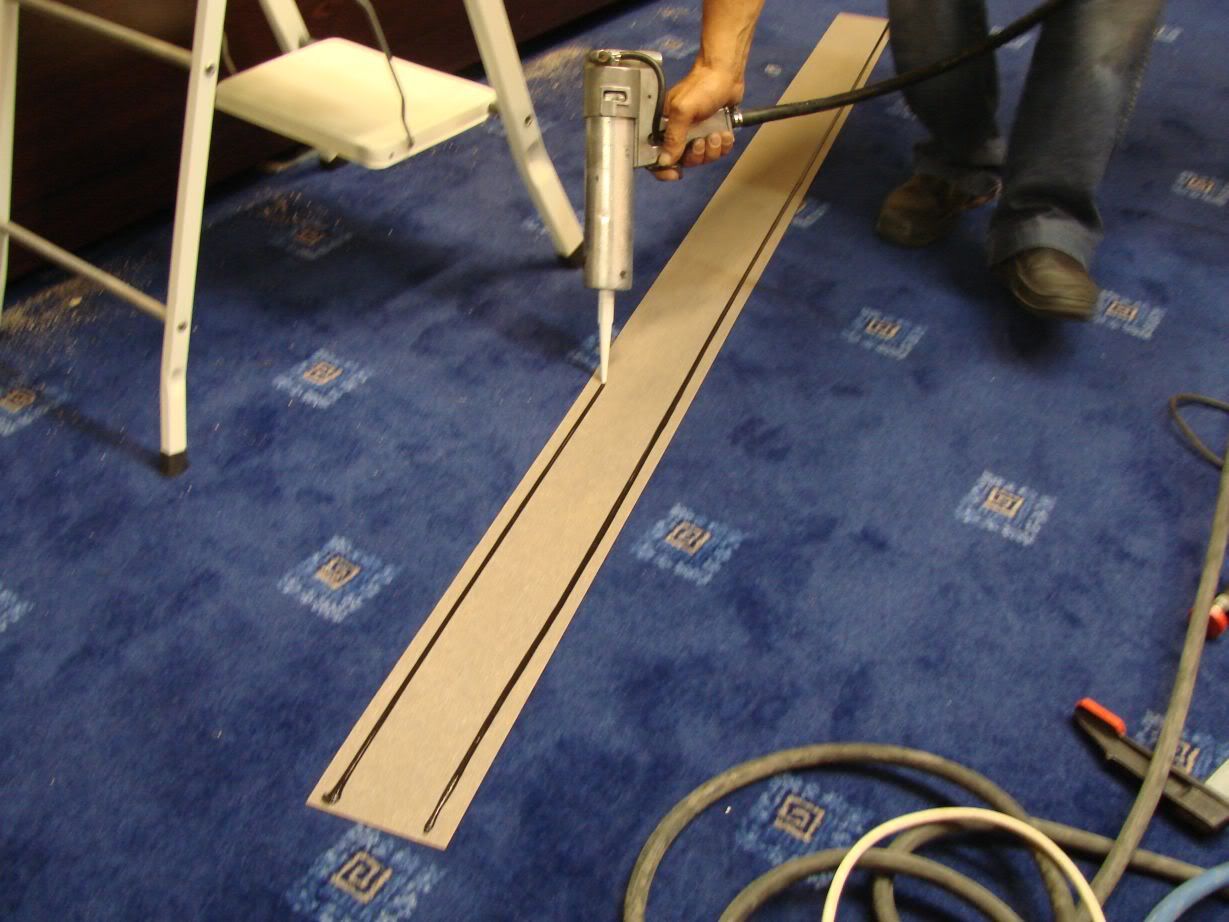

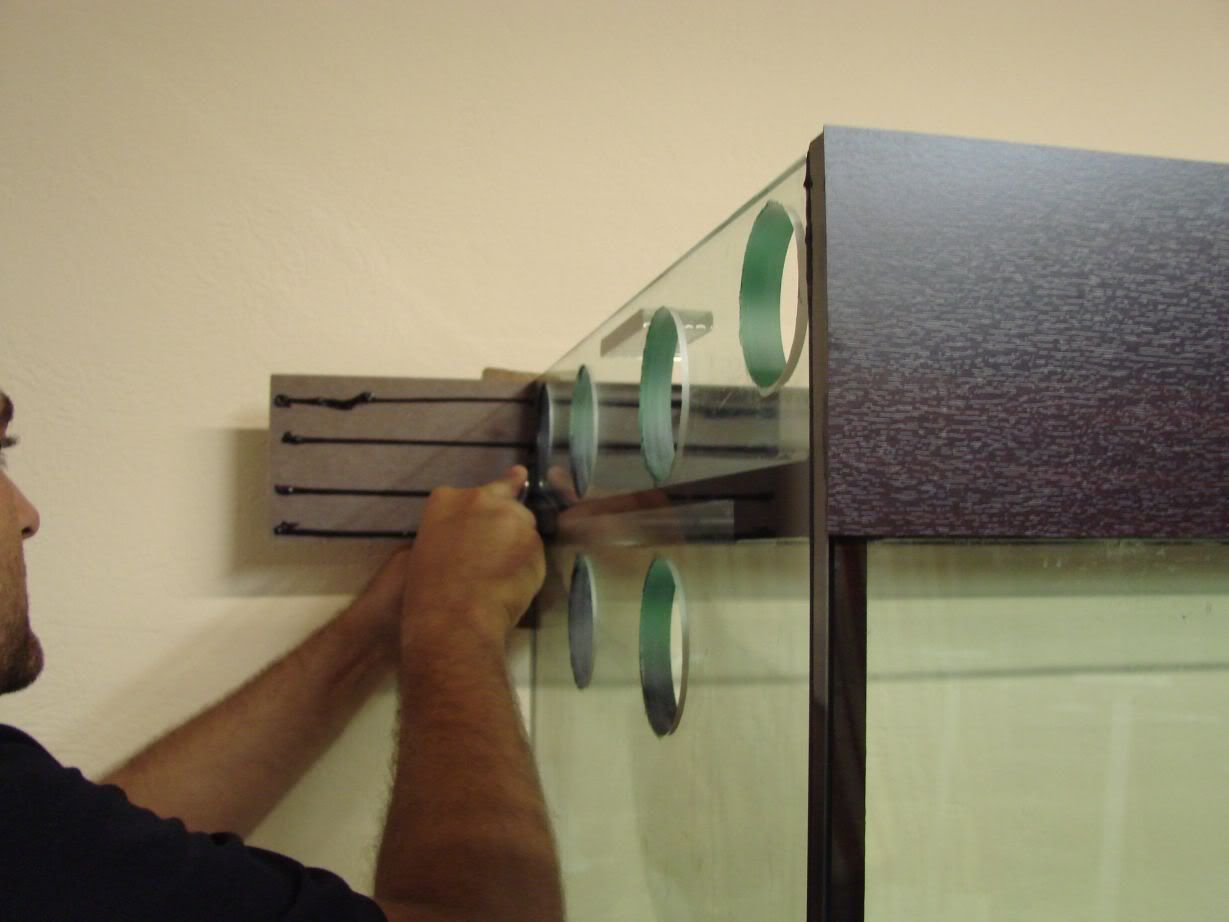

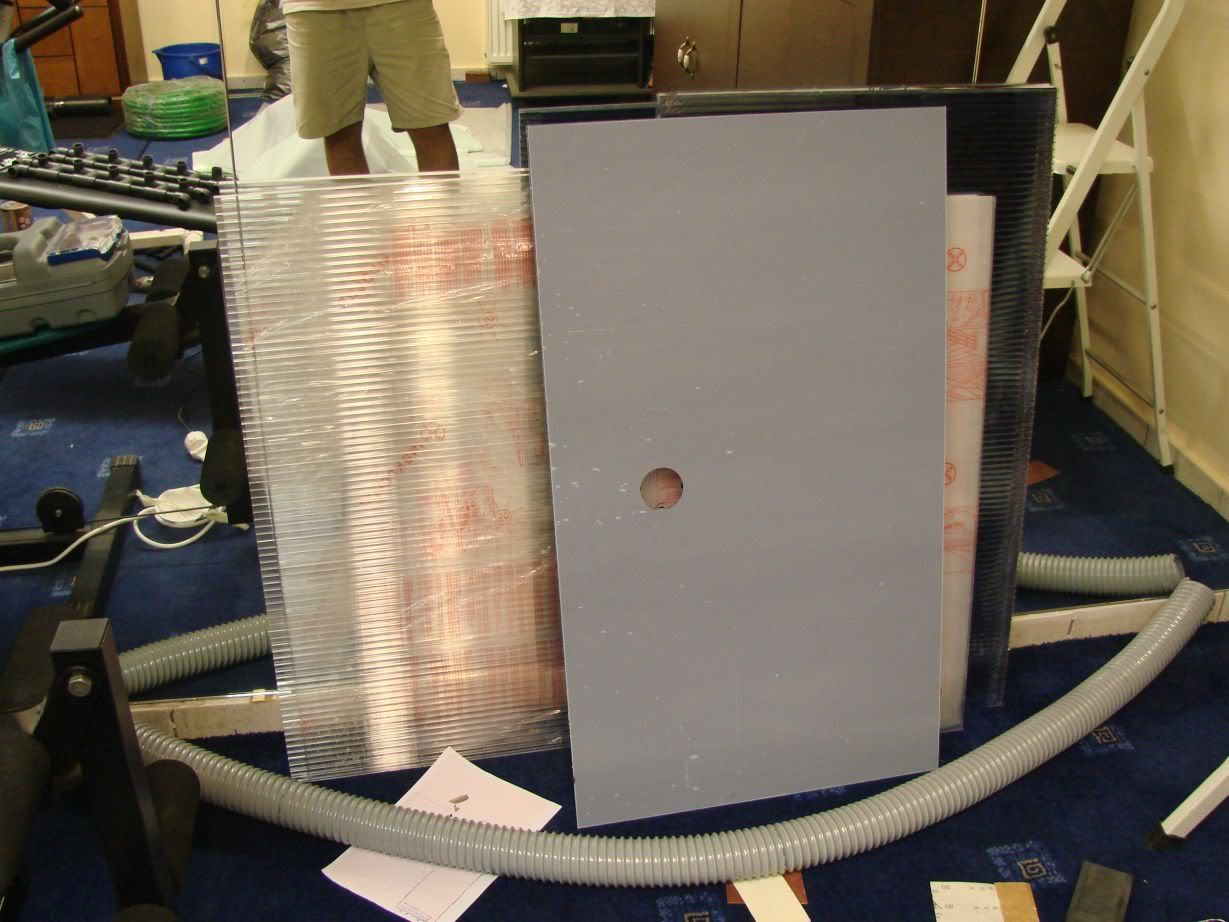

Then,before applying silicone,they cut part of the upper side formaka because it was protruding too much and would spoil the wall with silicone if applied as it was...The lower side formaika was protruding too and would also had spoiled the wood but they saw it just before it touched the wall and cutted broke pieces from it while on place...He uses the wood pice as a ruller for the cut...He cuts using a tool with a razor blabe...You will see the tool in a following photo...

Applying silicone...

Cutting and sanding and doing the same with the previous one...

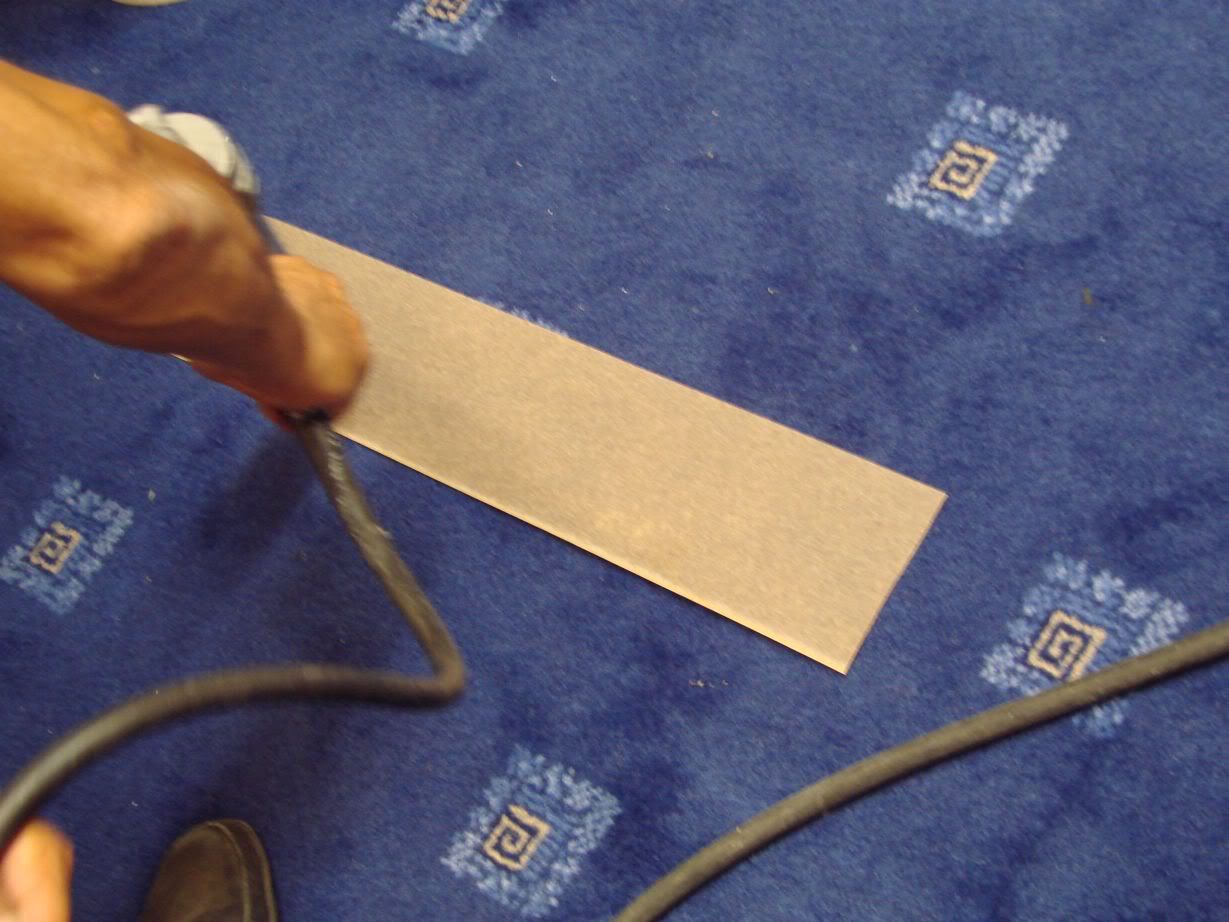

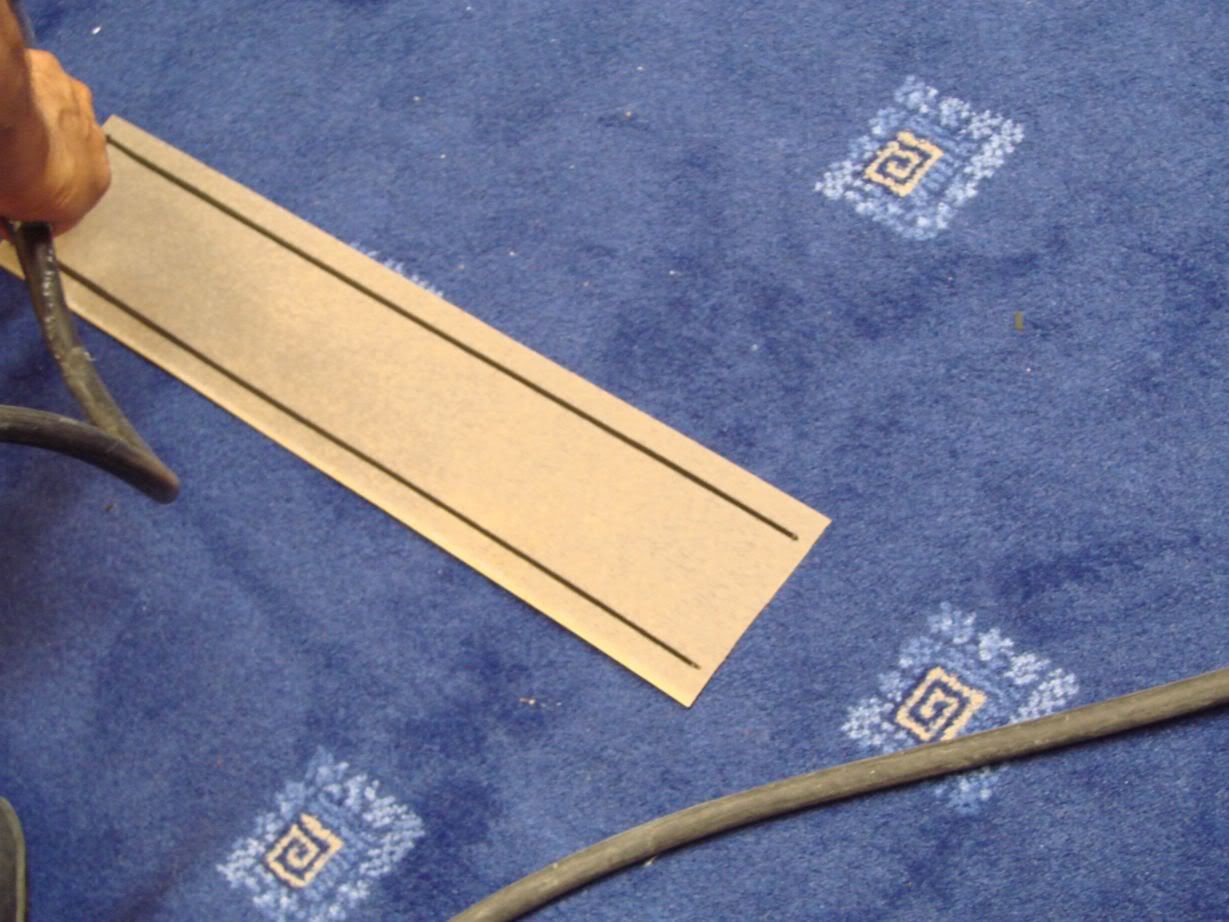

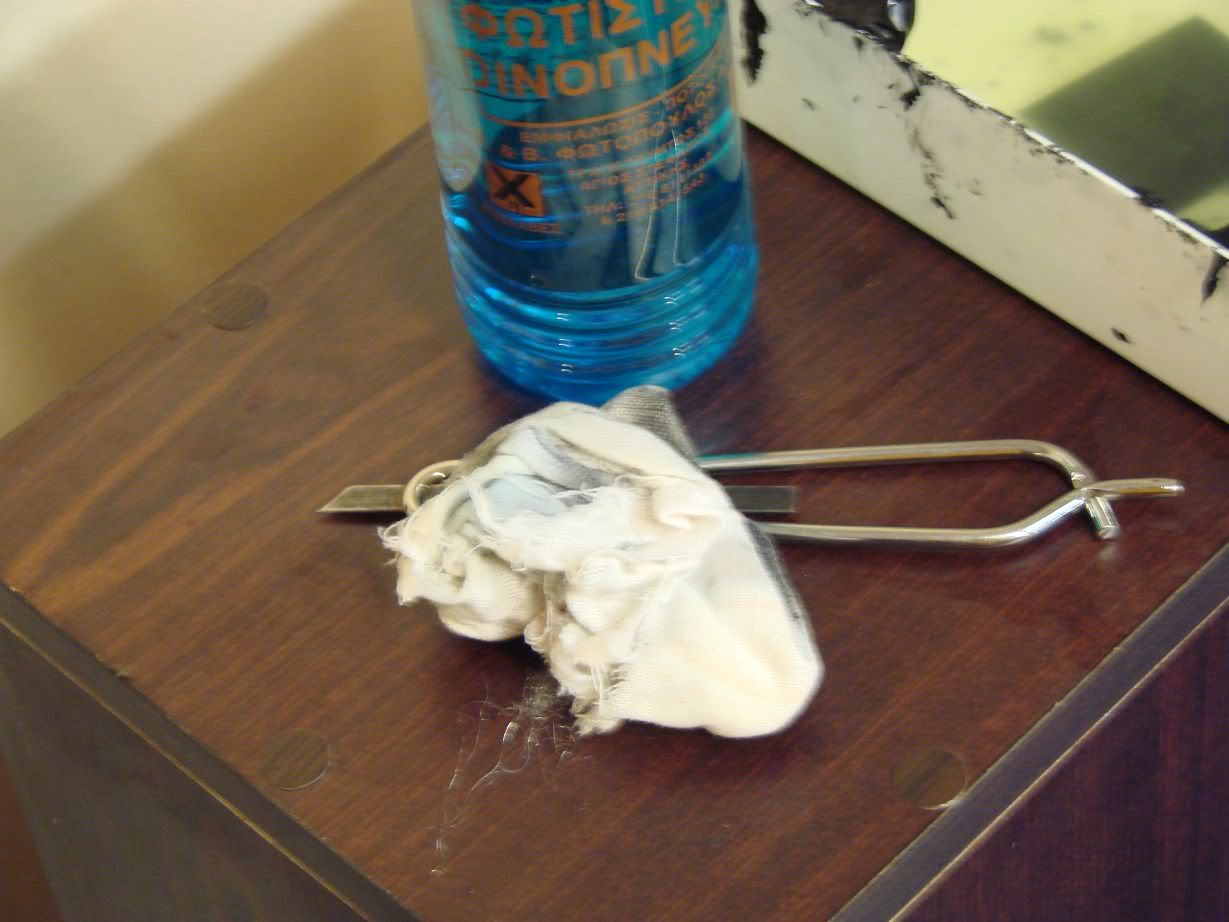

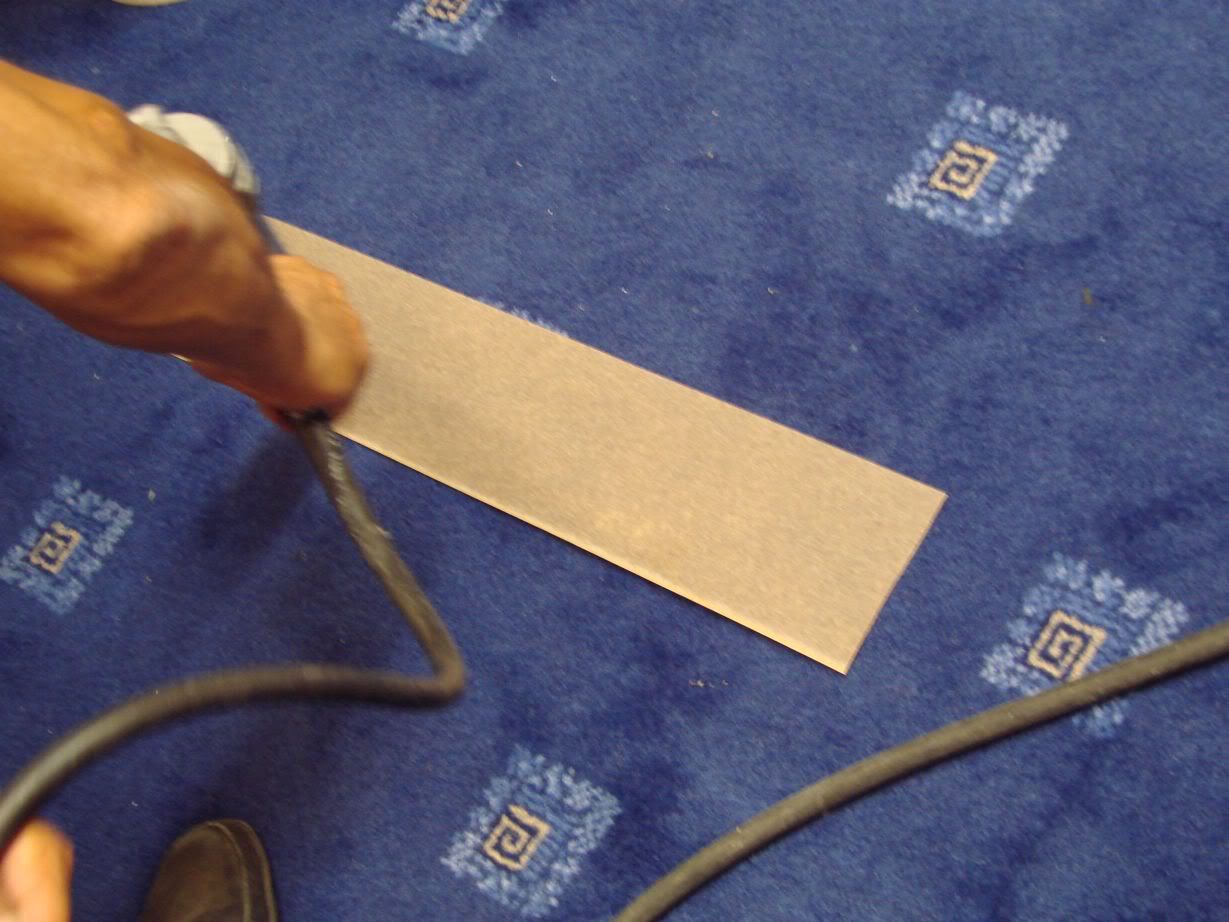

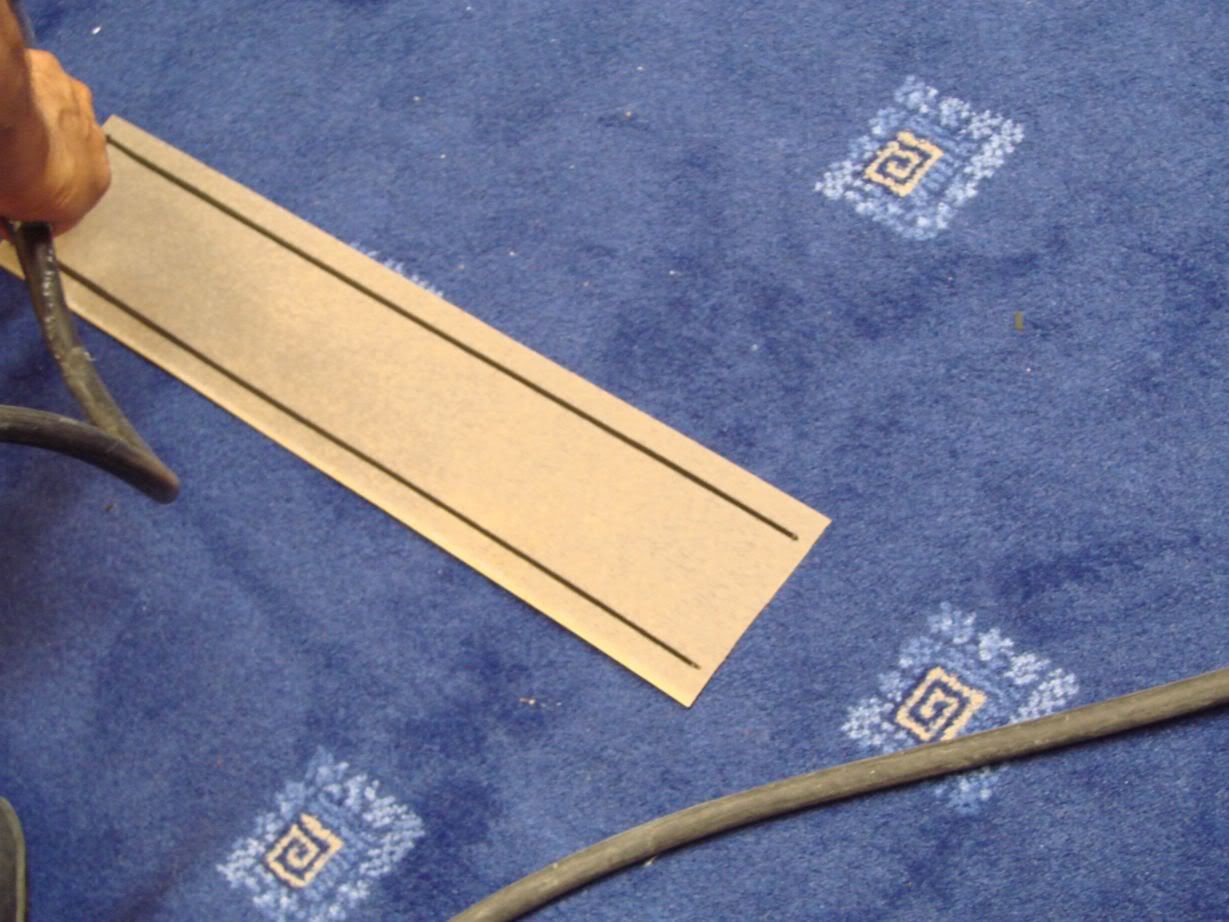

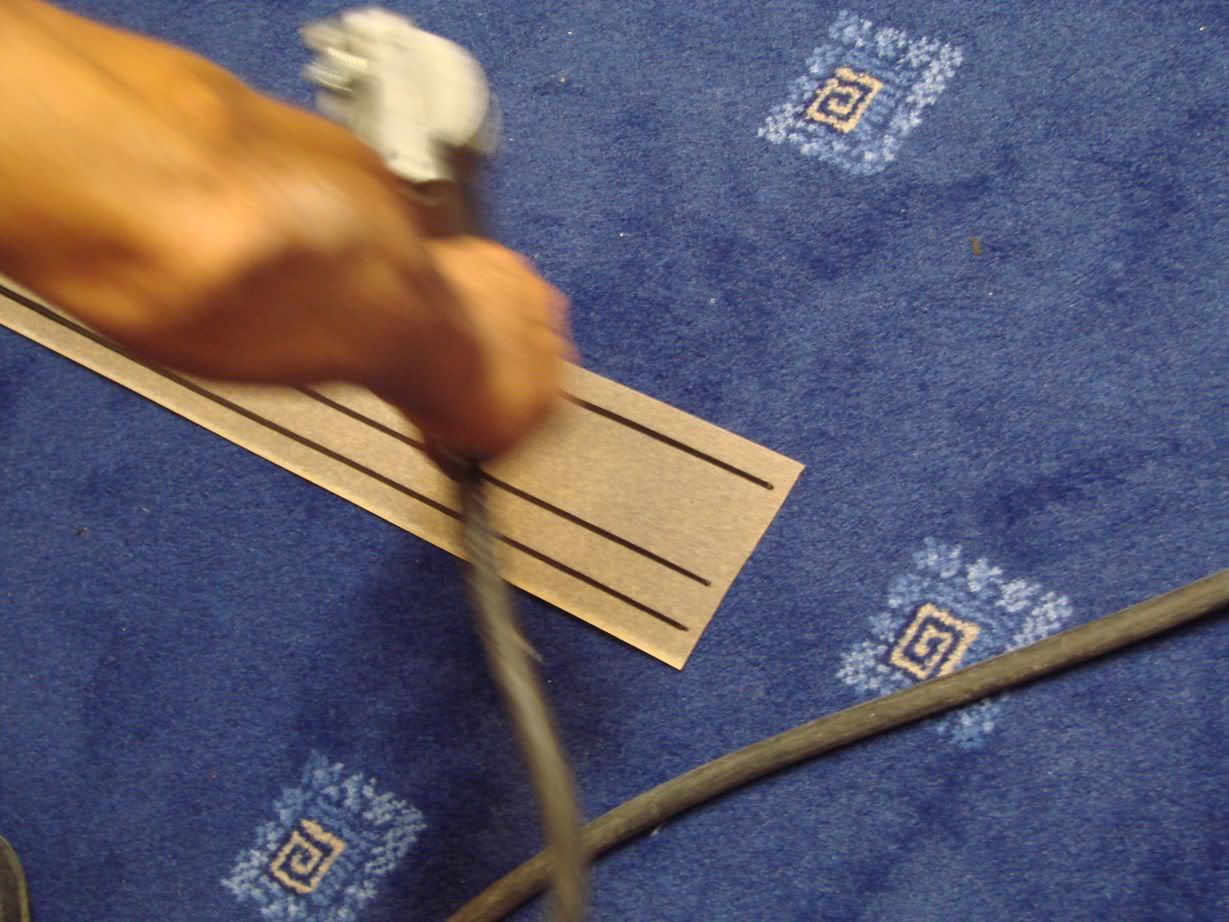

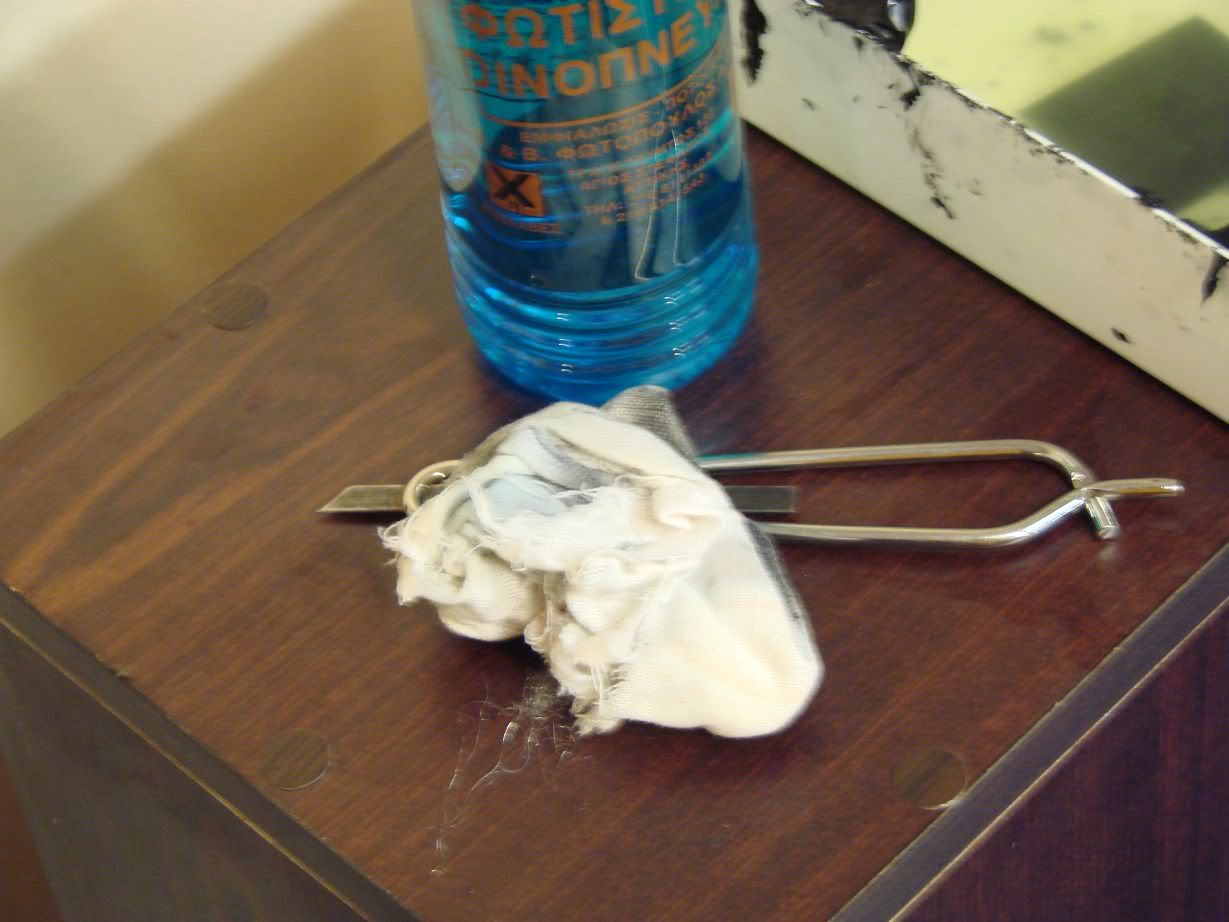

The tool used to cut the protruding parts of the formaikas...

Some photos of the tank as it was when they left...

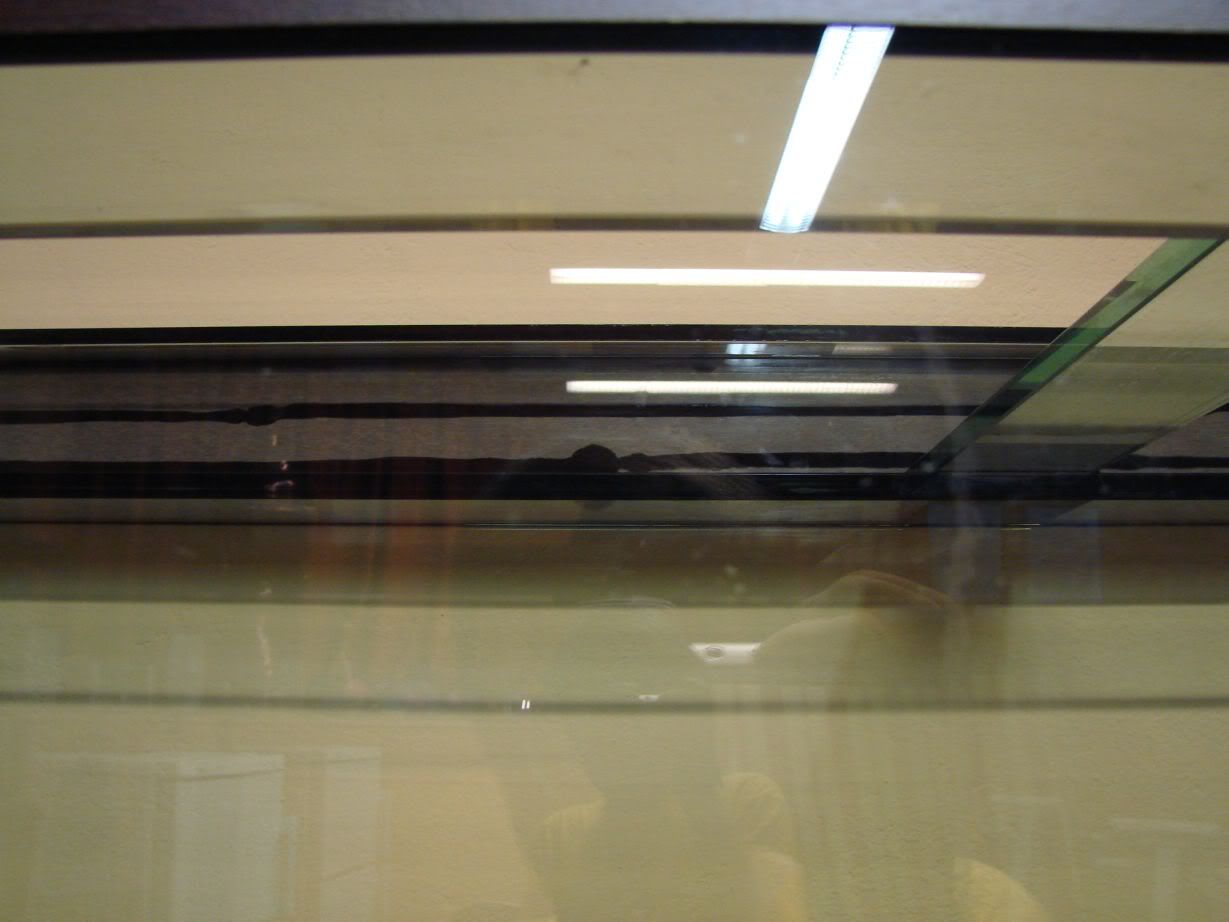

Left view of the inside with the rims in place...By the way,he is taking the dimensions for the inner and outter covers...

I forgot to say that they were putting tapes after they were finishing with all the above i said...

Whole tank view...

They came again the past Friday to finish everything...(in fact one came...).But again there were problems with teh overflow and it couldnt fit again,after being lowered 3mm...So he is gonna cut it 3 mm lower and glue new upper cover for the transparent ''teeth''...

Btw,i took 36photos that time...Will upload them when i can find some more time...Thats it for now...

Enjoy!

[Mod edit: fix broken image end tag --Mats]

Posted: 04 Aug 2007, 22:11

by grokefish

Whats happening???????

I wanna see!

Posted: 06 Aug 2007, 15:27

by Kostas

Hi grokefish,

Many more things have happend but they are not posted yet due to the time needed to do it...They will slowly be added...As of now, i have:Sanded the inside of the tank base to remove any paint that had fallen and pen marks and also to remove most burn spots from the wood(due to the welding...).Then,i applyed water soluble,eco varnish for outside use on the upper wood of the tank base.The sump and holding tank came and the sump connectors are installed.I am also done with the pvc construction for the powerheads(to have a river tank) and i am currently making a construction from slate that will have 4 different size pleco caves for Hemiancistrus subviridis and also two more individual and longer slate caves for the same sp..Also,i have already received the huge wood pieces i had ordered in January directly from Brasil...These woods are S. American tree surface roots mostly and are beautifull...These are the things you are about to see in the photos that will follow

For more than a week now i am at Skiathos for vacations and so no progress rignt now...And thats also the reason i am will not be posting any more photos for 2 more weeks...But when i return i will try to post all of them quickly

Have a nice Summer!!!

Posted: 11 Aug 2007, 16:03

by Kostas

Posted: 11 Aug 2007, 16:32

by Kostas

Now...the setting up begins!!!

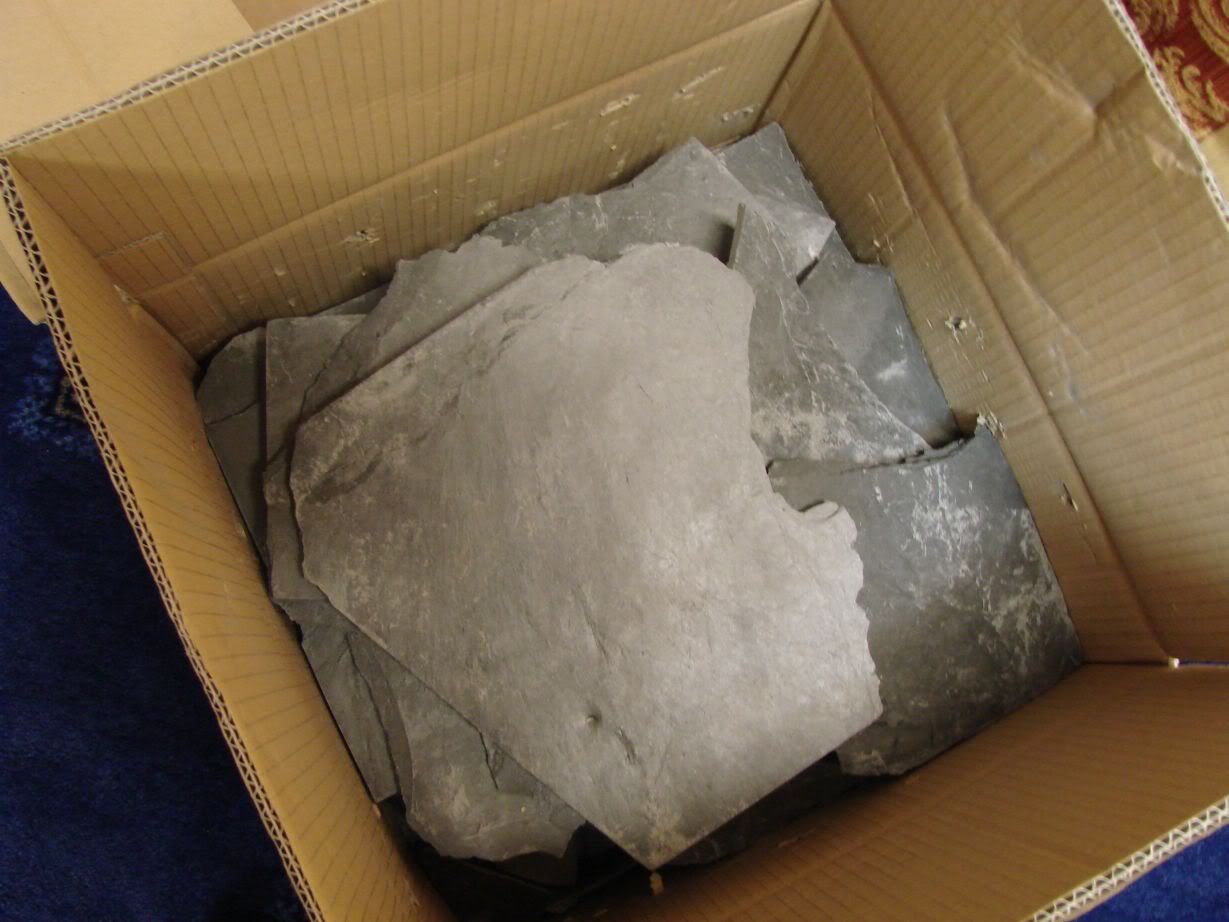

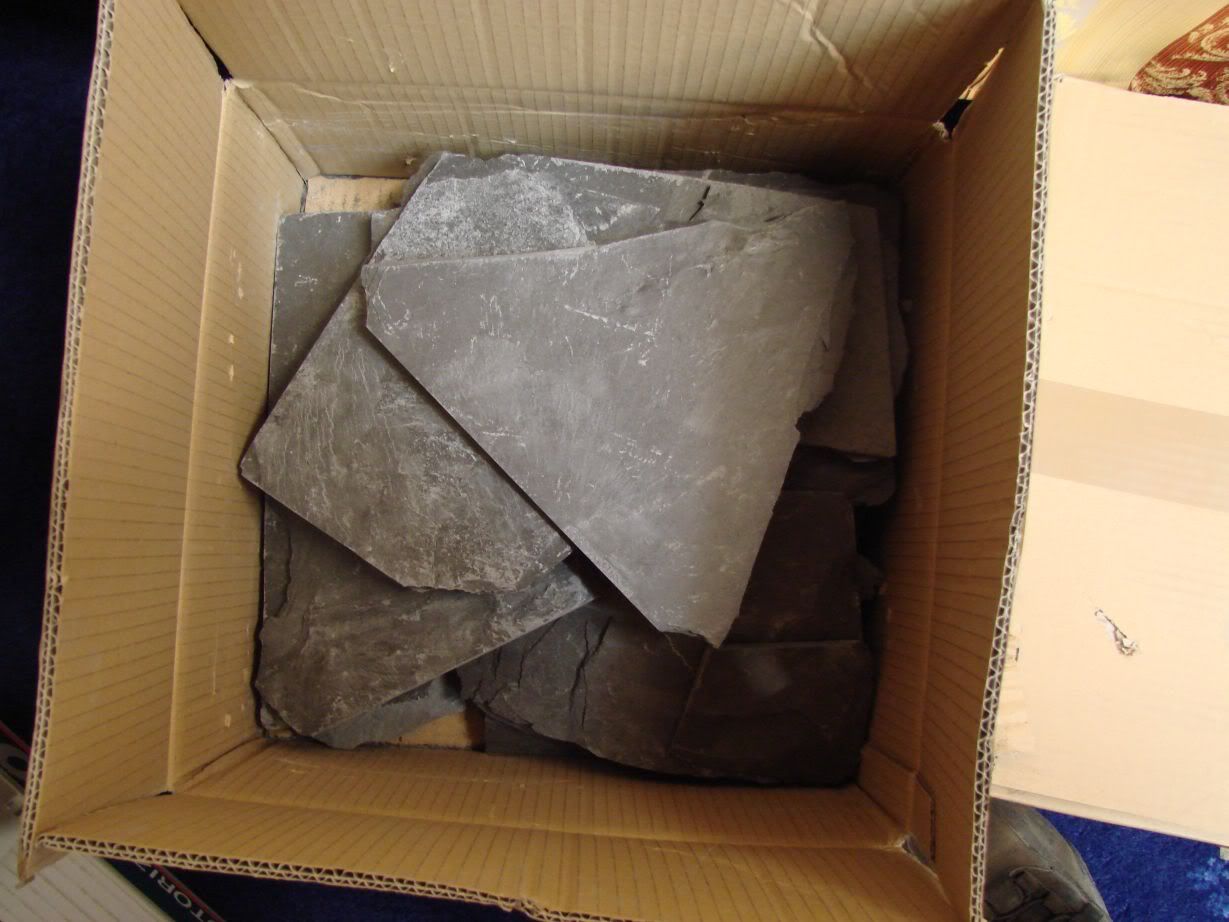

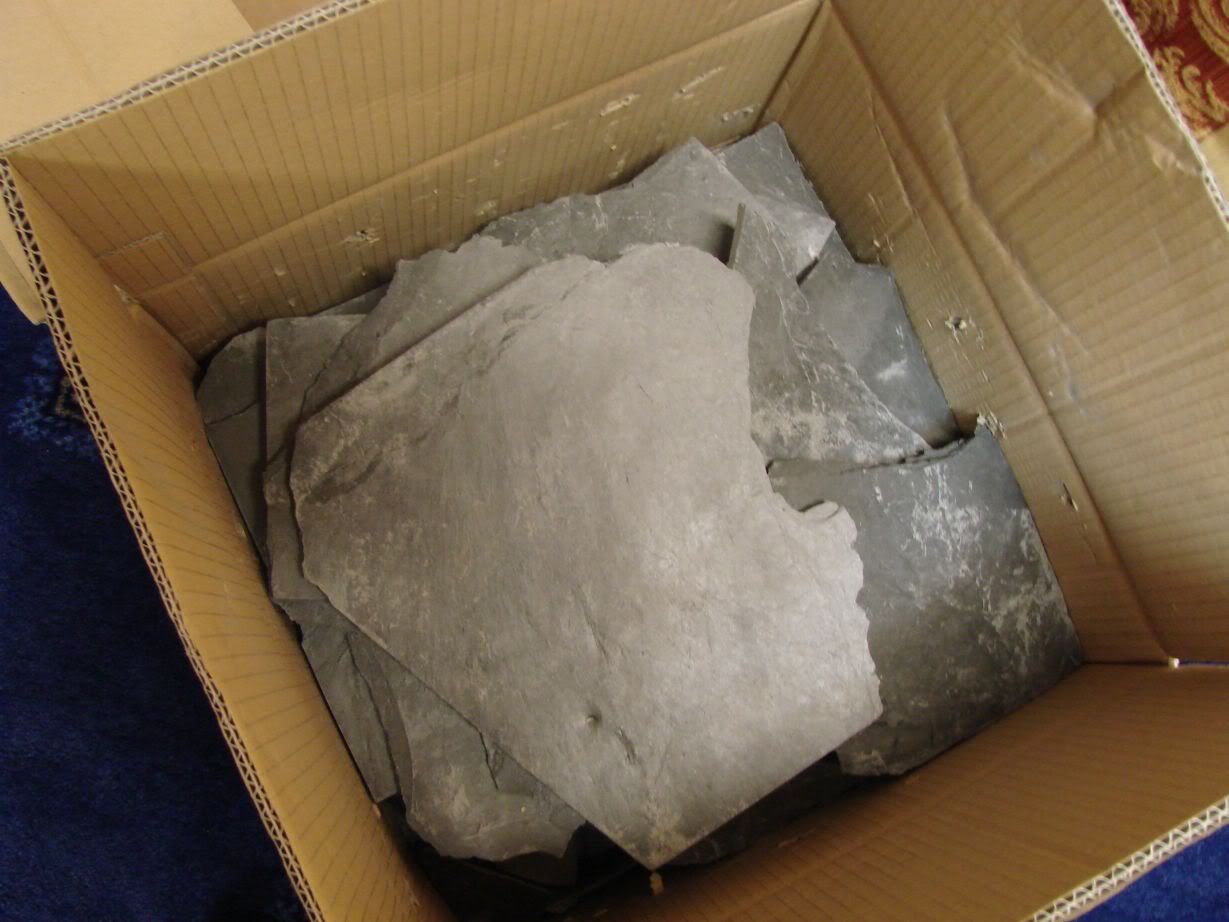

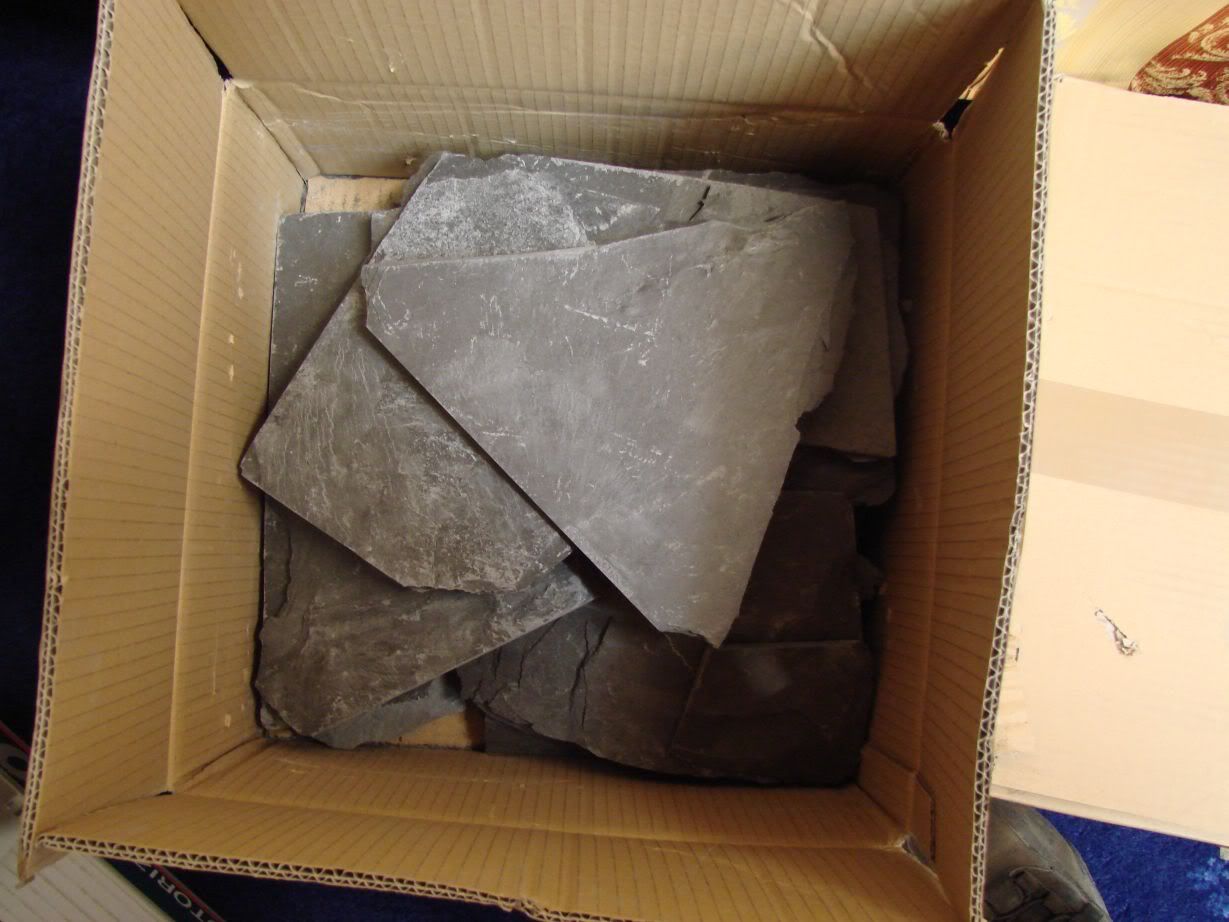

The boxes in which the slate came...Its 50kg of slate in total...

The slate...

Box 1

Box 2

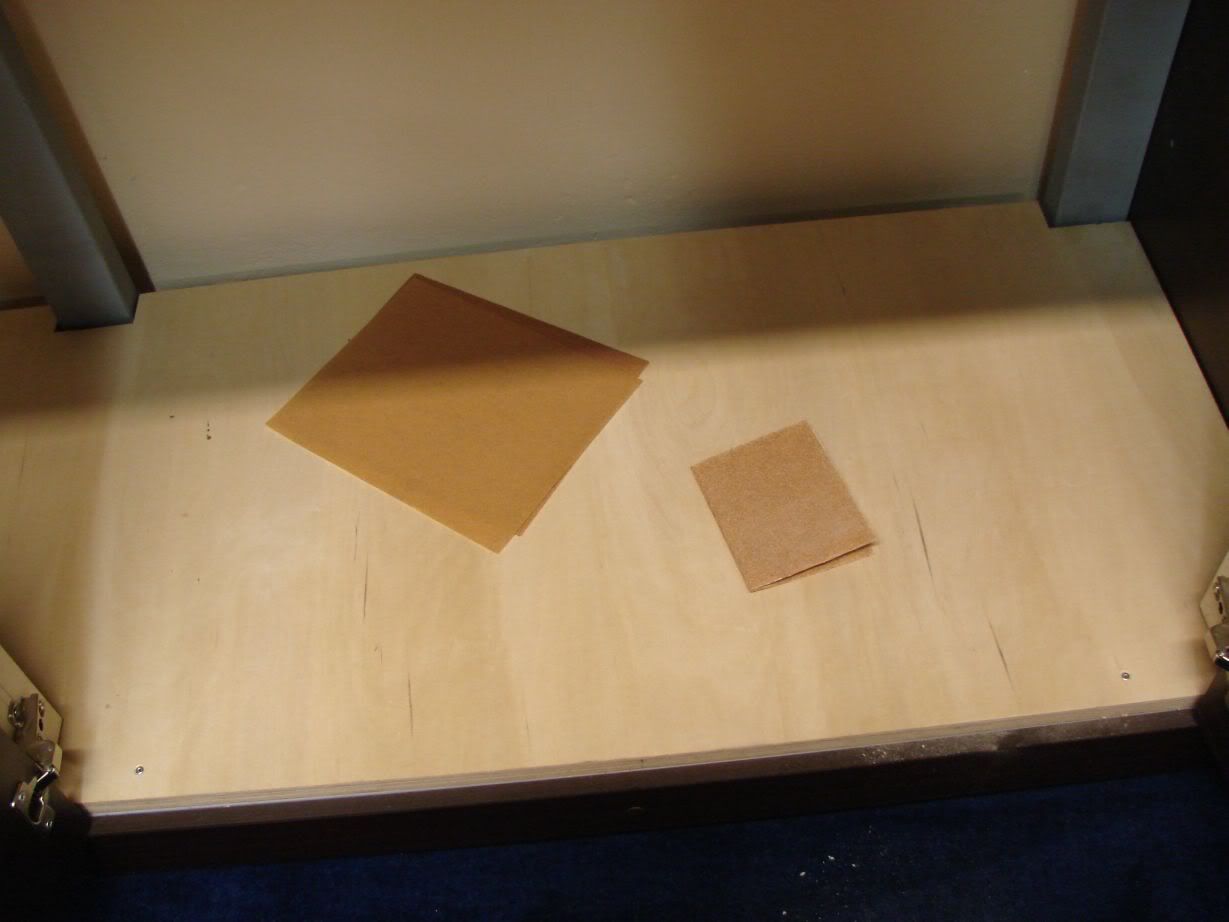

The tank stand floor is a bit dirty not smooth as you can see and so i am going to sand it to make it better looking...

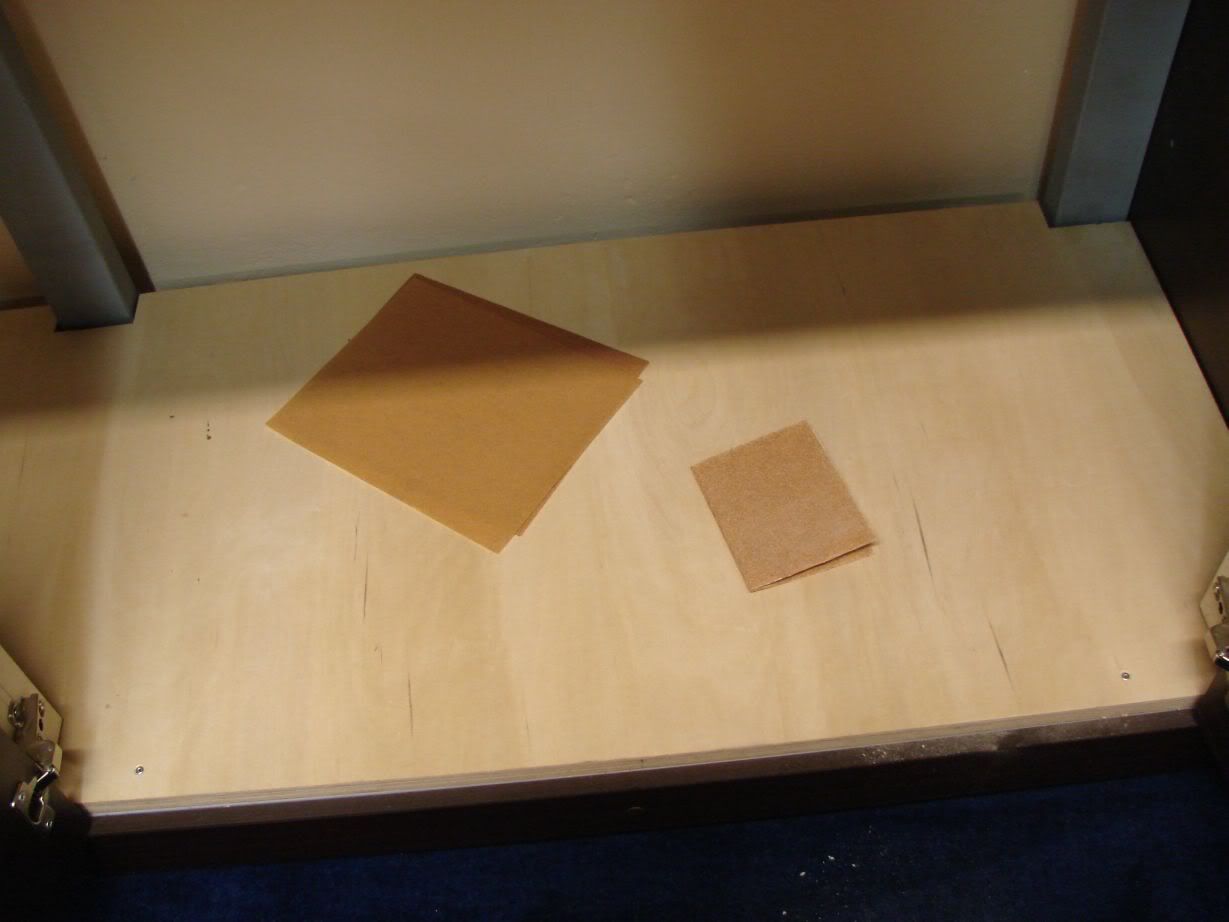

Tank stand floor before sanding...

Right side...

Left side...

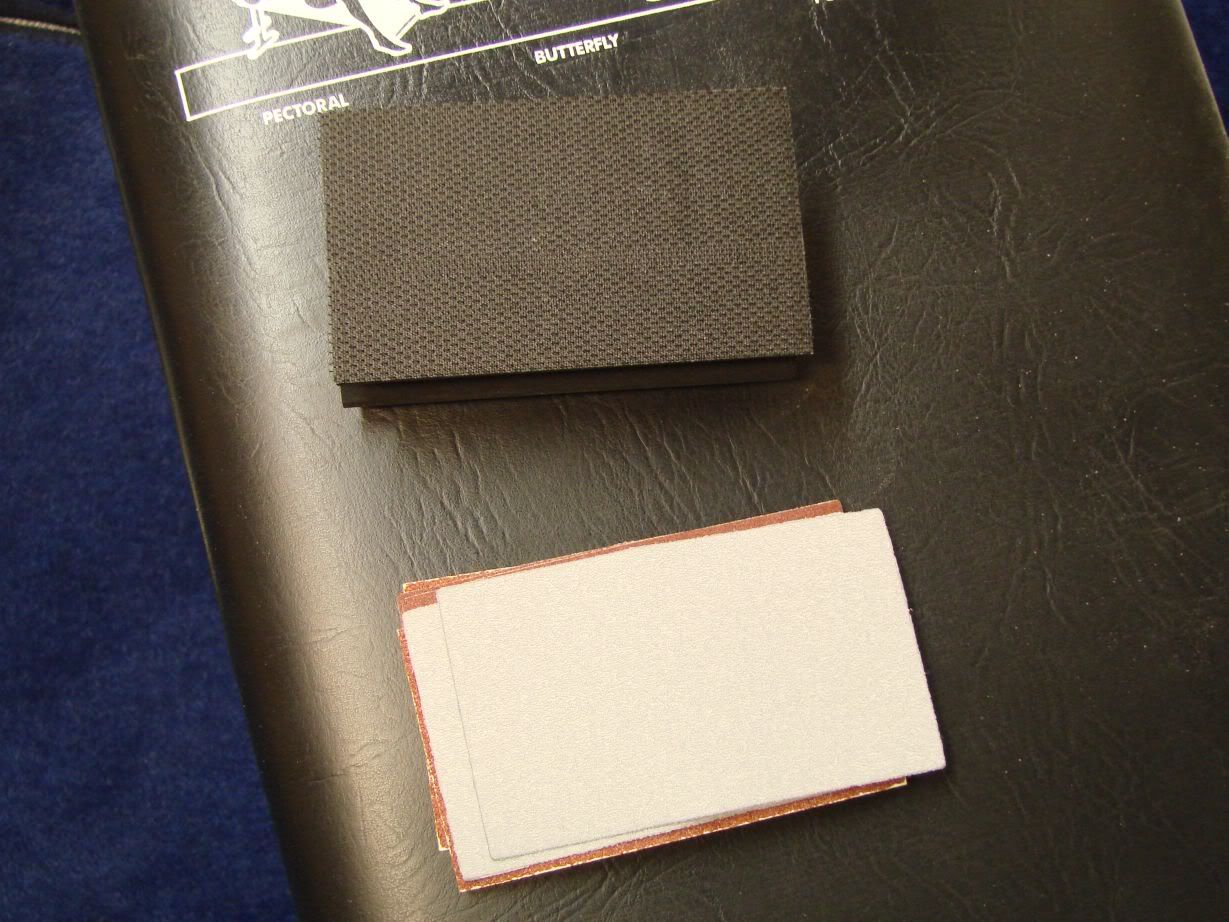

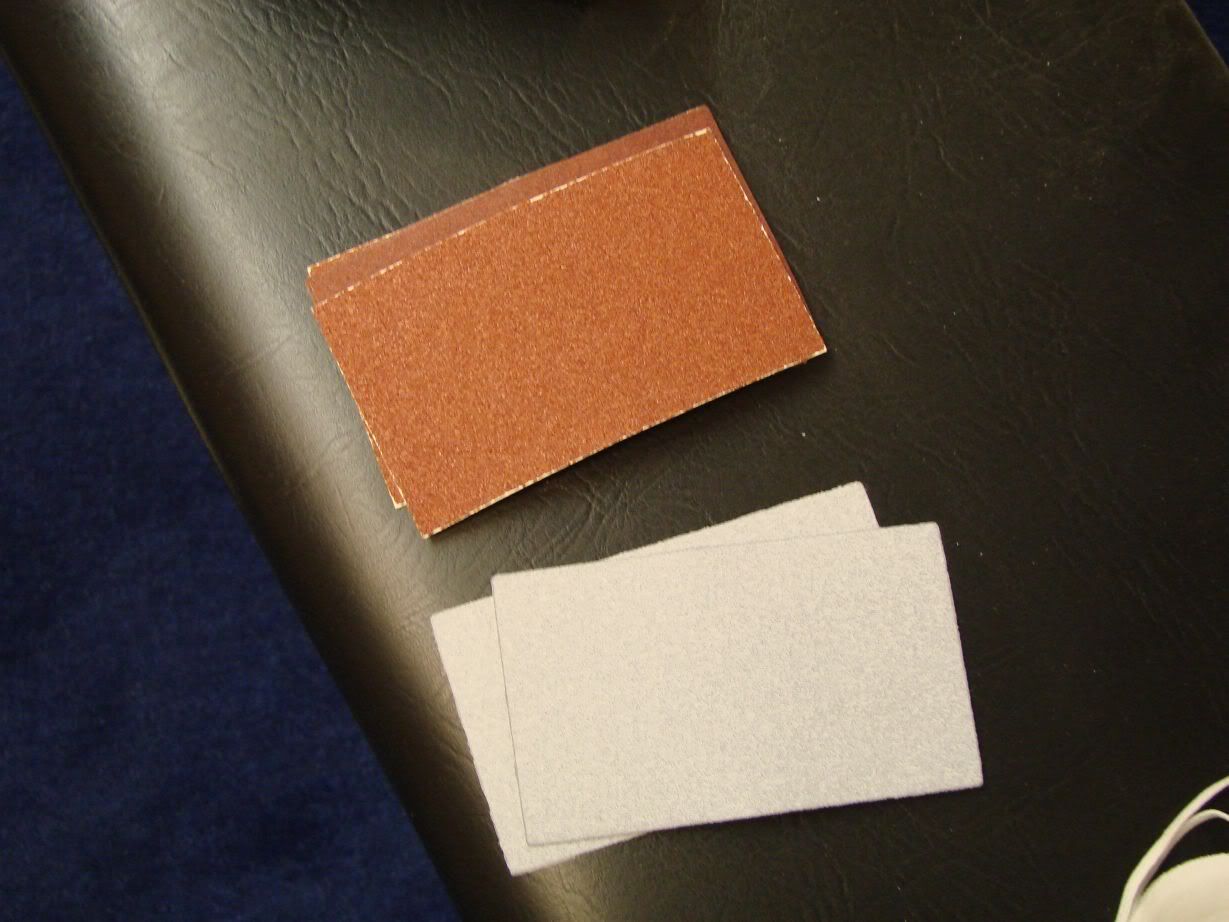

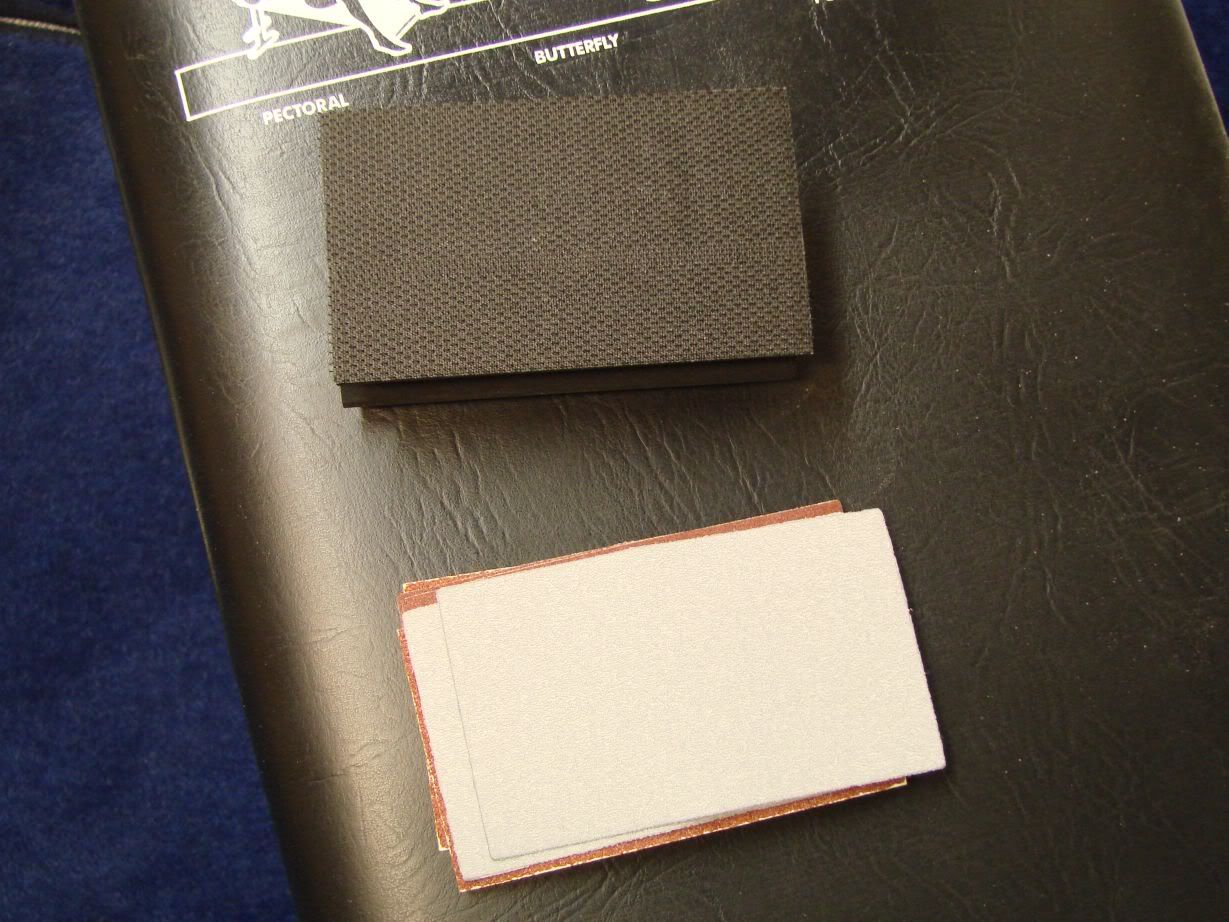

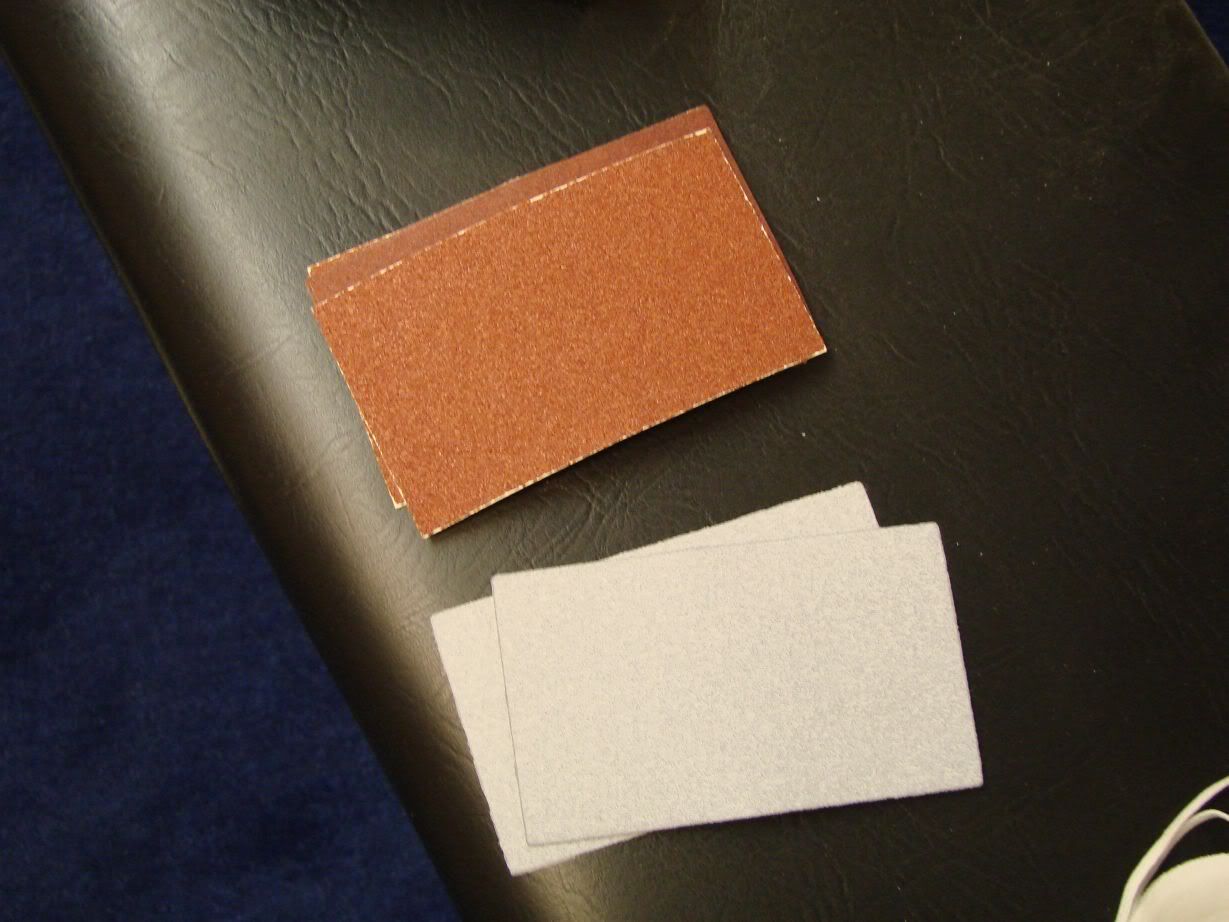

Sandpapers and the job begins...

...with all the safety precautions...

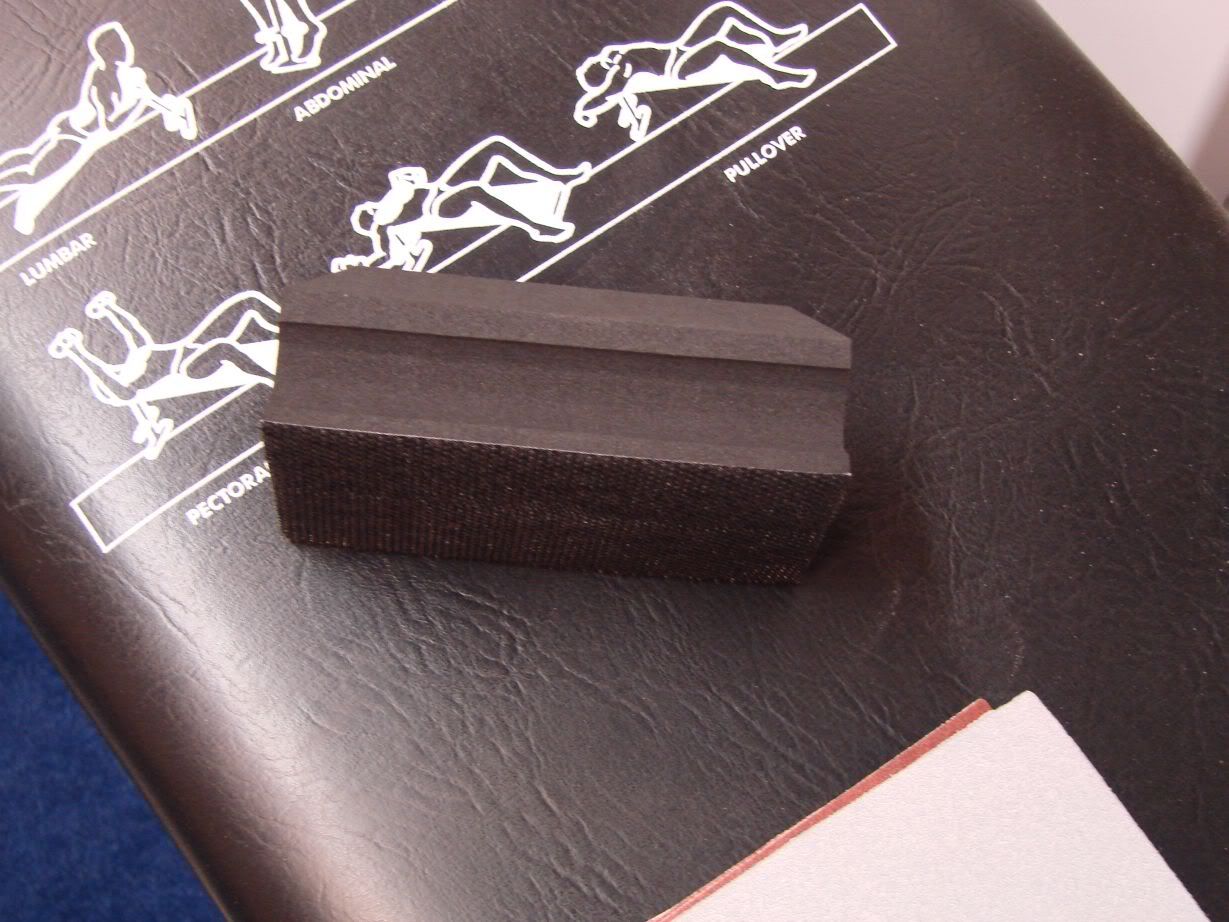

Because plain sandpaper was very tiring to use to the tank stand upper part(which needed much more sanding than the floor as it had numerous burn spots from the welding,i purchased a velcro holder and suitable sandpapers for it...

Tank stand upper part before working on it...

Washing themain tank...I used a realtively clean bucket after thoroughly rinsing it and the with an eco wettex i cleaned all the tank from soaps starting from the cleaner parts...I then changed water and redid that wipping out water with paper towel...So now the tank sparkles and is crystal clear...I forgot to say that i firstly scooped the sawdust and other bigger useless stuff with a vaccum...

On the work...

And after...

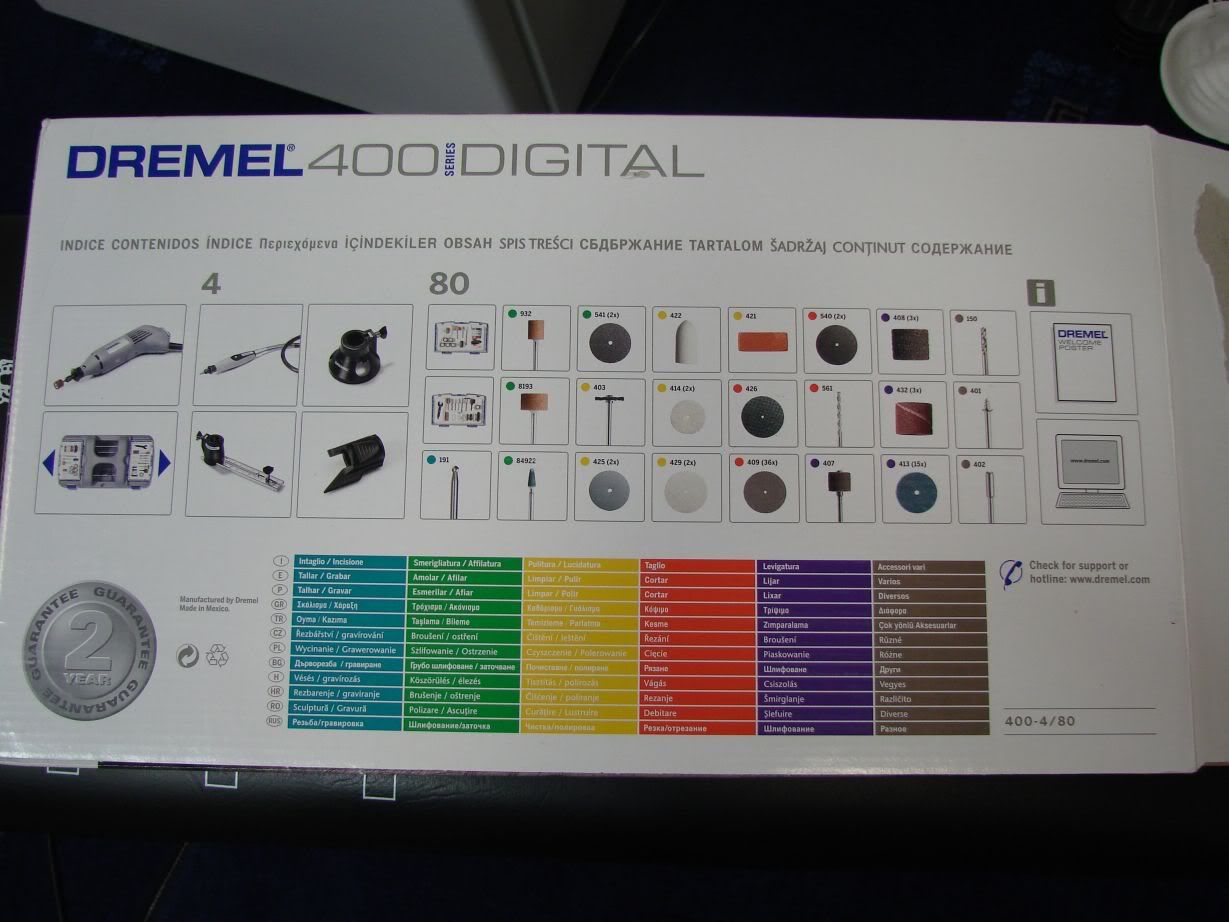

Now back to the sanding job,in the end i used an electric sander i had forgotten i had and sanding was finished in 5 minutes for the upper part...In the lower i usued the manual way because i was sanding small marks...

The electric sander...

Posted: 12 Aug 2007, 16:48

by Kostas

Posted: 12 Aug 2007, 17:43

by Kostas

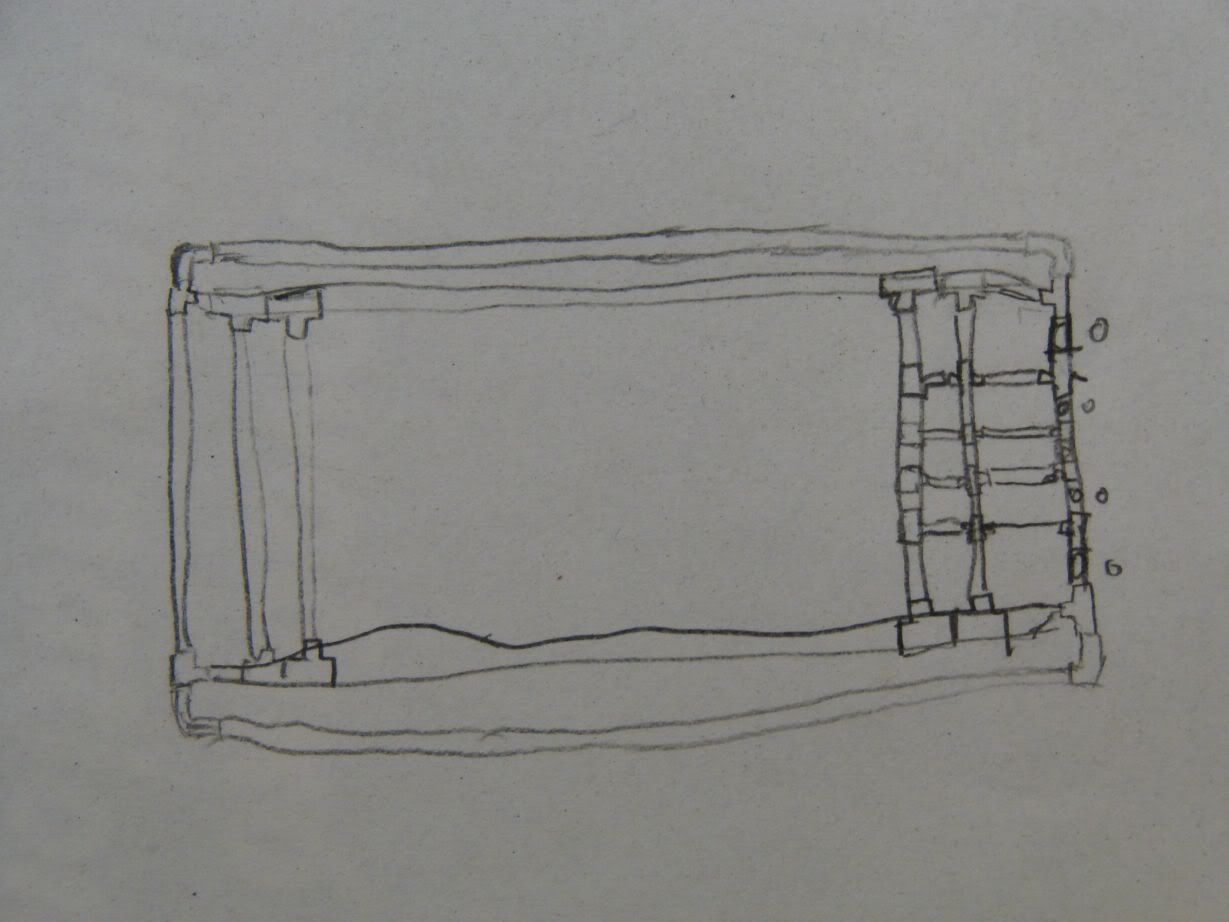

On the above plan,the same fittings i draw at the right side,go to the left side too...The circles next to the drawing,mark the places of the powerheads...

But it wasnt that easy...When i place all the fitting i needed to have on the small sides and measured them,i found out that they were longer than the small sides of my tank...So,i needed to make them fit someway...So,i thought of cutting 0,5cm from each side of each fitting and doing some maths before doing it,it would make the plan feasible...And so i did and everything went ok...I marked the fittings that would be used for the small sides and cutted them with the Dremmel and then made them smooth with a sanding tool of the Dremel again...Then,i cutted the small pieces of pvc pipes for between the fittings...So here are the small sides,test fitted...

These two were the difficult and very tiring part of the job...They took me hours to make them...

That evening,the South American woods i had ordered this January finally came!!!!!!!

They were all great!!!More on that along with a photo a bit later...

Later that evening,Andrew from Hydrocosmos came and broght the overflow,sump,holding tank and tank hoods and installed the overflow hoses...There arent photos of the proccess as i was helping a bit there...

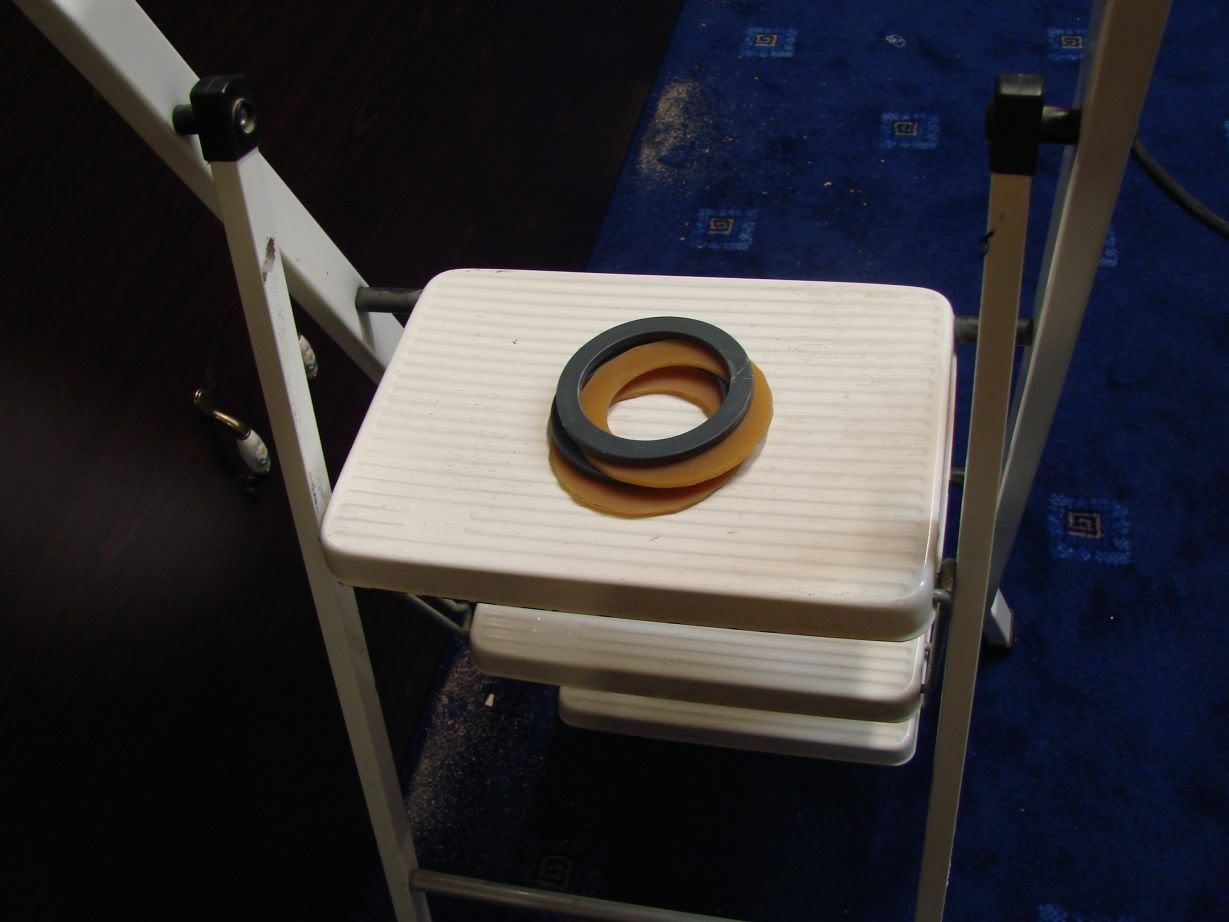

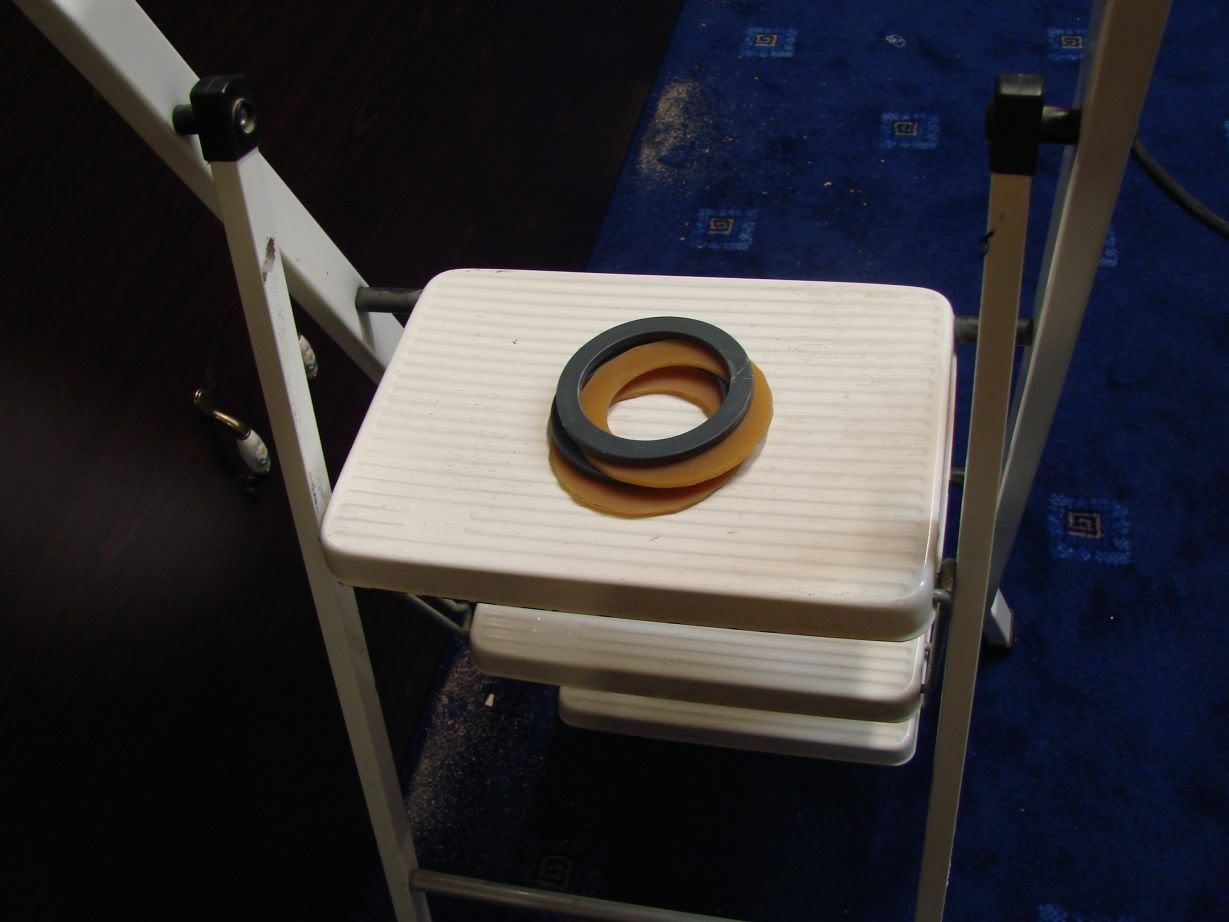

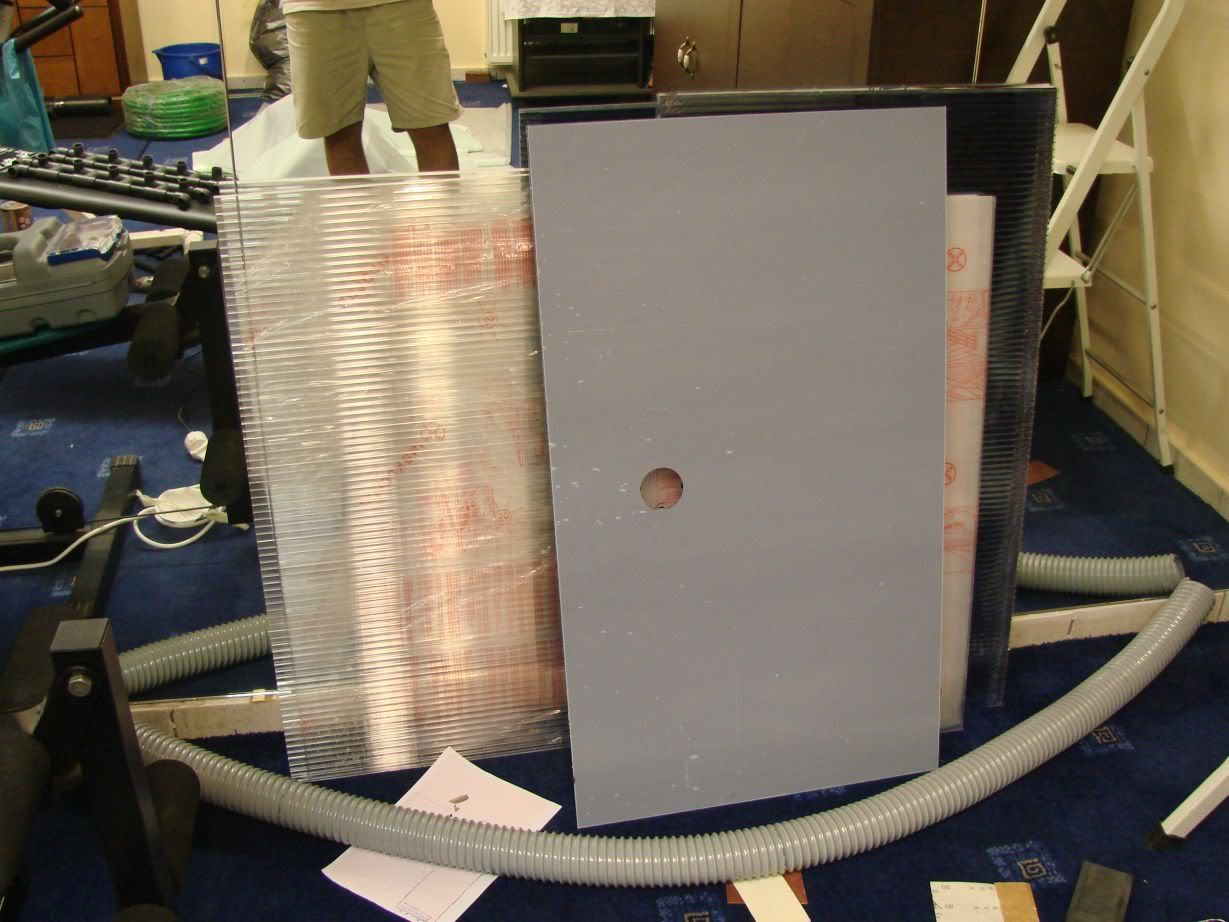

The overflow finaly fitted!!!Even this time,it took as a lot of time to install it as the o-rings were pushing the overflow out and also there is nowhere to hold the pipes that stik out of the overflow from so that they dont go in again and make screwing the elbows almost impossible,especially with the teflon...

The teflon used...Its very wide...

Tank covers and leftover hose from making the overflow piping...It says that its ducting pipe and that really bothers me...

He says its safe and he was the one who bought it for my tank...What do you think?Is it safe?I am really concerned as not all plastic is drinking water safe and this one doesnt say anything about that...Its made for air anyway,not for water so there was no single chance that it would say something like that...

What would you do?Would you use it or change it?

Now,on the woods...

I used three of the woods that came...The first was a really big and heavy piece,measuring 160-70-80cm(lenght,height,width).The wood maust weighted at least 80-90kg...

We managed to put it in the tank(breaking the upper front and side formaica a bit

and we saw what we should cut to make it fit...So we cutted one branch firstly withy a saw and then broke it so that it looks natural and the wood was ready...We putted it in again with no further damage to the formaicas and then we cutted a small protruding part of the wood that would not let the inner covers close...Then we fitted two more smaller woods,about 25 and 40kg respectively...And here is the end result...

Now,continuing with the pvcs and to make a long story short,i followed the plan letting the fittings for the other parts of the pvc network were size wasnt an issue,at their original size...Here are the small sides finished...Only glue is missing but i want put glue till i test fit them in the tank and make sure everything is ok...But i will first finish with the slates and then glue the pvcs...

This is my progress till now...The only other ting i have done is that i have put all the slates out of the boxes and have found the pieces i will use for the caves and the slate building...I will take photos when i return home as i am on vacations now...I had uploaded all the photos i hadnt posted before i go so than i could post them from an internet cafe

Hope you liked it!!!

Posted: 12 Aug 2007, 21:43

by apistomaster

Hi Kostas,

I really like your overflow design. Very 21st Century.

I am sure, in my career as a professional structural inspector of 27 years, I have inspected the construction of many sophisticated reinforced concrete storm water runoff detention systems far less complex. I do envy your ability to hire professionals to handle much of the construction. I also think all your materials are fish safe.

Sure is a lot of wood you plan on including in the aquascape but I'm sure it is about as realistic representation of a portion of a river bottom as one could ever hope to create. I would start thinking about finding some fish traps should you find you ever have to remove any fish. That could be a nightmare.

Of course, I know how much thought you have put into your stocking plan so I am joking(mostly) about fish extractions.

I for one, am looking forward to seeing the completed set up.

We have had many pm's regarding your flow though system but I am still not quite sure I understand where your return flow manifolds will be placed.As you know, mine are much simpler and are vertical with only one "T" just below the water line and another 90 degree elbow at the terminus near the bottom; each are independently adjustable to any desired flow direction. I only went for a Discus friendly Lagos-like gentle flow( diffused ten X tank volume/hour) and not a riverine environment.

Anyway, see you when you come back from vacation.

Posted: 12 Aug 2007, 23:38

by Haavard Stoere

Reading this has been a fantastic journey. I wouldn´t be surprized if you actually managed to breed the Hemiancistrus subviridis in that tank. Looking forward to read more about this wonderful project.

Enjoy your holiday:)

Posted: 13 Aug 2007, 17:42

by Kostas

Thank you very much for your replys

I am glad you like it so much apistomaster

I designed it...

Andrew told the constructors how big to make the holes for the overflow hoses...And i generaly oversized it because i plan on having floating plants and want it to not clog easily as most overflows do...So you can understand that i am very happy you approve it

I am glad you find the looks of the wood very natural...Thats what i alway had in mind and tried to do when selecting the wood pieces and positioning it...I will do add a few more pieces that i hope will make the tank look even more natural

I too hope i wont have to pull any fish out...Not for the efford required to catch it in there but because this would mean thats its in bad shape...

I am still thinking about how i will make the return...Its not set yet...I want to first finish with the powerheads(the Tunze havent arrived yet,i have ordered them about 2 months ago and still havent arrived because they are in shortage all this time...Tunze was getting a large order from the Americas ready and didnt supplyed noone with its products till it was done with it...And imagine that i am buying them from the

supplier of aquaristic.net,a big German online shop that needs many of them weekly...He currently has only 1 and we are waiting another one...As for the other powerheads,i will decide only when the Tunze arrive...),the slates and every work i want to do on the tank stand(i plan on painting the metal skeleton for my own piece of mind than no primer will contaminate the water by chipping into the sump or by water spilling on it and falling back into the water...) before i proceed to the sump setting up...But when i do the setting up of the return i will post many photos of it so that you can see clearly how it is...

And as for your Discus tank,i still wonder how the Discus are ok with all the flow you have in there!!!

I have never seen a Discus tank with so much flow!

Have a nice Summer!!!

See you!

I am glad you liked it Haavard!!!

I hope that too

Thank you

Have a nice Summer too

Posted: 22 Aug 2007, 22:20

by grokefish

Hi Kostas,

This thread and that tank are marvelous, it's really going to be worth the effort you have applied and I think it will be very realistic. those pieces of wood you have are great where did you get them?

Between you and Haavard you guys have enough patience to watch a glacier move down a mountain, I wish I had such patience, I would have tried to do it all in a day and it probably would have been a disaster.

Excellent work and I am on the edge of my seat waiting to see it finished.

Matt

Posted: 23 Aug 2007, 16:06

by apistomaster

Kostas wrote:Thank you very much for your replys

I am glad you like it so much apistomaster

I designed it...

Andrew told the constructors how big to make the holes for the overflow hoses...And i generaly oversized it because i plan on having floating plants and want it to not clog easily as most overflows do...So you can understand that i am very happy you approve it

I am glad you find the looks of the wood very natural...Thats what i alway had in mind and tried to do when selecting the wood pieces and positioning it...I will do add a few more pieces that i hope will make the tank look even more natural

I too hope i wont have to pull any fish out...Not for the efford required to catch it in there but because this would mean thats its in bad shape...

I am still thinking about how i will make the return...Its not set yet...I want to first finish with the powerheads(the Tunze havent arrived yet,i have ordered them about 2 months ago and still havent arrived because they are in shortage all this time...Tunze was getting a large order from the Americas ready and didnt supplyed noone with its products till it was done with it...And imagine that i am buying them from the

supplier of aquaristic.net,a big German online shop that needs many of them weekly...He currently has only 1 and we are waiting another one...As for the other powerheads,i will decide only when the Tunze arrive...),the slates and every work i want to do on the tank stand(i plan on painting the metal skeleton for my own piece of mind than no primer will contaminate the water by chipping into the sump or by water spilling on it and falling back into the water...) before i proceed to the sump setting up...But when i do the setting up of the return i will post many photos of it so that you can see clearly how it is...

And as for your Discus tank,i still wonder how the Discus are ok with all the flow you have in there!!!

I have never seen a Discus tank with so much flow!

Have a nice Summer!!!

See you!

I am glad you liked it Haavard!!!

I hope that too

Thank you

Have a nice Summer too

Hi Kostas,

Discus like more flow than most people seem to think. Here they are.

Posted: 27 Aug 2007, 09:36

by Kostas

Thank you very much for your replys

grokefish,

Thank you very much for your kind words!

I ordered the woods from Brazil through a pet shop in Greece whose owners is very cooperative and a good man

Eh,why you say this?

Thank you for the compliment

We just really cant think of setting up our tanks before we are done with all the details we want them have...So its not much of a wait for as,its work...

But you too did a wonderfull job with your fishroom...And managed to do everything in very short time,thats an accomplishment!!!

apistomaster,

Yeah,that seems as yours are in perfect condition...

But how much flow do they have where they live?More or less than that?

Unfortunately,i am going to be very busy that month and will not be able to do much if any regarding to the tank setting up...

So the project will be delayed even more...

I cant wait for the time when i will be done with the slates,its a nightmare!

Just an update,at Friday i went to a company that sells pebbles and other stones and has a great variety,and found the large basalt rounded smooth stones i wanted for my tank...They are between 15-25cm each and will see how i will position them after i am done with the slates...Also,i bought chimney black tiles that its from India...This is slate right?I bought this too as it will make my job with the caves easier...

Also,i am done with painting the tank stand skeleton black,i painted it with black car paint...This is not toxic when dry right?It says that it shouldnt be used in places children could chew or continually lick(cant find the correct word for when you place something in your mouth and the lick it for some time in there...

)Do you think its ok?

As for the overflow hoses,they dont state they are made of Pvc...Will they be ok?

I will post photos of the sump and holding tank soon and also close up of the overflow hoses print...

Thank you very much in advance

Posted: 28 Aug 2007, 00:32

by MatsP

Kostas wrote:Also,i am done with painting the tank stand skeleton black,i painted it with black car paint...This is not toxic when dry right?It says that it shouldnt be used in places children could chew or continually lick(cant find the correct word for when you place something in your mouth and the lick it for some time in there...

)Do you think its ok?

Yes, I think that's fine. As long as it's not submersed or continually dripping water into your sump from the stand - in which case I'm pretty sure the toxicity of the paint is less of a problem than the other consequences...

Also, the text on your paint will probably be the same whether it's bright green or black. Black is a colour that is relatively easy to make non-toxic from a pigment standpoint. Of course, the rest of the paint may contain components that are toxic, such as the resins and softening additives (to prevent cracking) - but I doubt that it's REALLY harmfull unless you really have water running off/over the metal for a long time...

As for the overflow hoses,they dont state they are made of Pvc...Will they be ok?

In the US, PVC pipes are used for water supply to houses. I think polypropylene (or some such) is more common in Europe, but PVC pipes are available for waste-water and such in Europe.

I wouldn't think that PVC is a problem for overflow pipes.

--

Mats

Posted: 28 Aug 2007, 07:59

by Bas Pels

Most likely they are PVC - especially if you were able to glue them with PVC glue. That stuff soes not glue anything else, that is, I never found anything which I could glue with PVC glue. It certainly does not glue PPC (polypropylchloride)

Polypropylene can not glued with anything, it can only be connected with other sheets by smelting is. Not a nice task to perform in house

Posted: 28 Aug 2007, 08:01

by Kostas

Hi Mats,

Thank you very much for your reply

Thats why i used it because it will generally have nothing to do with tank water...The primer was really annoying because when you touched it was leaving dust of itself on your hand,something that could cause problems as i may have to touch the stand unintentionally to reach in certain places and probably even to clean the sump...So with this should be ok to touch it and then place hand in tank,right?

I am not worried about the pvc,i know its ok and i have purchased pvc pipes special for drinking water...

My problem is the flexible piping of the overflow...It doesnt say its Pvc and says its for ducting...Do you have any idea regarding what it may be made of and if its safe?

Thank you very much in advance

Posted: 28 Aug 2007, 11:01

by MatsP

Kostas wrote:Hi Mats,

Thank you very much for your reply

Thats why i used it because it will generally have nothing to do with tank water...The primer was really annoying because when you touched it was leaving dust of itself on your hand,something that could cause problems as i may have to touch the stand unintentionally to reach in certain places and probably even to clean the sump...So with this should be ok to touch it and then place hand in tank,right?

Yes, I'm sure of that.

I am not worried about the pvc,i know its ok and i have purchased pvc pipes special for drinking water...

My problem is the flexible piping of the overflow...It doesnt say its Pvc and says its for ducting...Do you have any idea regarding what it may be made of and if its safe?

Thank you very much in advance

Not sure on that - does it need to be flexible ducting? I don't THINK it's bad, but it's better to be safe than sorry.

Bas: I got my plastics confused, it's not PPE, it's MDPE (Medium Density Polyethylene), and no, you don't glue that together, you use an insert to prevent the pipe from collapsing and compression fittings.

See this.

--

Mats

Posted: 28 Aug 2007, 15:28

by Kostas

Thank you very much for your replys

Bas,

I am sorry,i didnt saw your message before as i was writting mine for some time...

No,its not glued as Mats said,it is just inserted over a pvc tube and has a compression fitting holding it...Some pvc glue has accidentally fallen at the edge of the pipe...So i will check if it has glued it well or not...As for pvc glue,it sais it also glues PU and ABS plastic...

Mats,

I am glad you are sure on that!

No,it doesnt need to be flexible ducting,thats simply what they brought me and installed...

Of course its better safe than sorry and thats why i ask,if i need to find something else to replace it or not...

So,if i understand correctly you are sure its MDPE right?

Has anyone been using this kind of piping in his tanks for some time?

Thank you very much in advance

Posted: 28 Aug 2007, 15:33

by MatsP

Kostas wrote:Thank you very much for your replys

Bas,

I am sorry,i didnt saw your message before as i was writting mine for some time...

No,its not glued as Mats said,it is just inserted over a pvc tube and has a compression fitting holding it...Some pvc glue has accidentally fallen at the edge of the pipe...So i will check if it has glued it well or not...As for pvc glue,it sais it also glues PU and ABS plastic...

Mats,

I am glad you are sure on that!

No,it doesnt need to be flexible ducting,thats simply what they brought me and installed...

Of course its better safe than sorry and thats why i ask,if i need to find something else to replace it or not...

So,if i understand correctly you are sure its MDPE right?

Has anyone been using this kind of piping in his tanks for some time?

Thank you very much in advance

No, the MDPE is what is used in the UK (and probably elsewhere) for pressurized water distribution, instead of PVC that is often used in other places. I would be perfectly happy with MDPE in the tank or as a duct for water to/from a sump. But I haev no idea what the material is in the flexible part - any chance you can find who the manufacturer is and see if they have any recommendations for it's materials.

--

Mats

Posted: 29 Aug 2007, 07:56

by Kostas

A,ok...

I checked for manufacturer yesterday and it says ALFADOM-Italy or something like that but searching with google i didnt find something realted to flexible piping...Maybe i am spelling it wrong,will check again today and see...It doesnt say what plastic is made of but it does say a UL and V number...Will write them down and post them today...

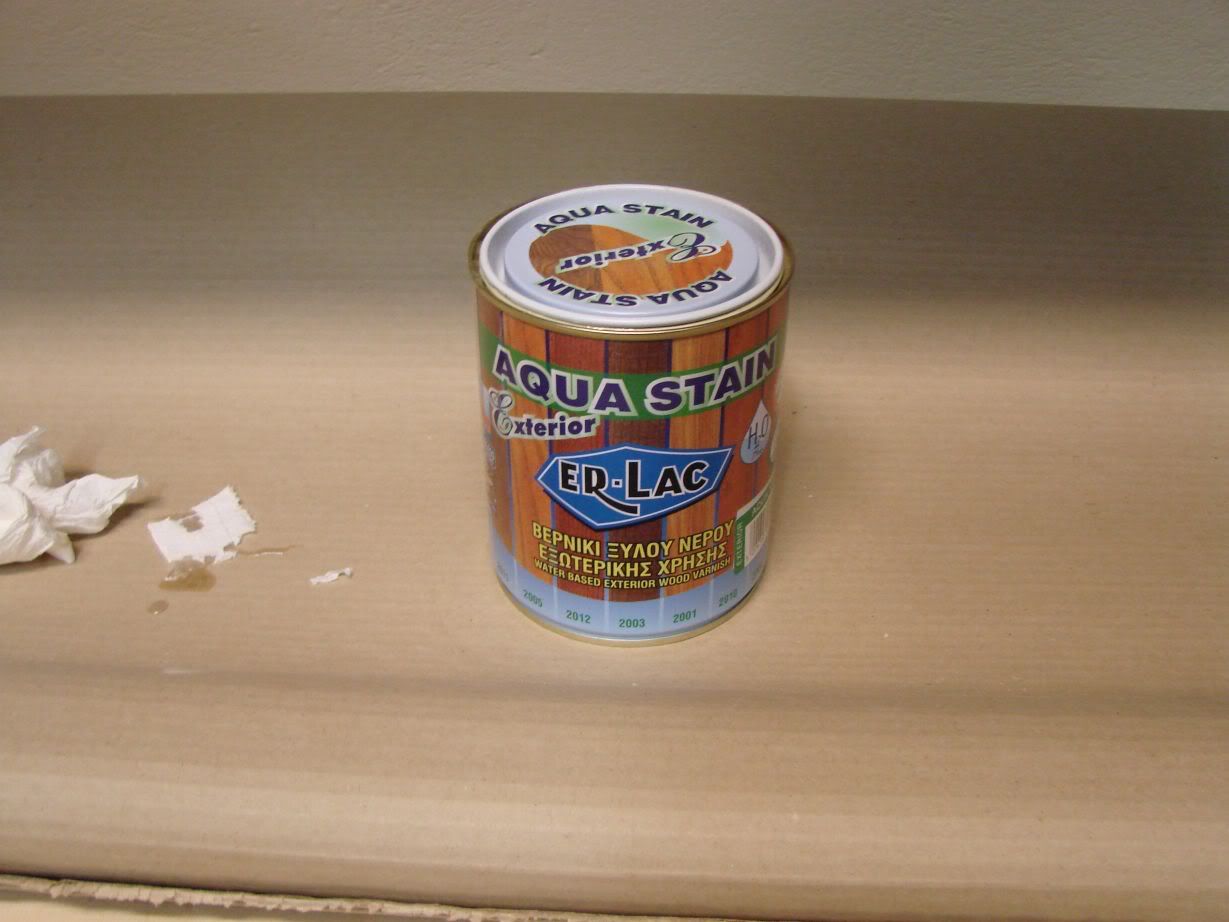

And an update on the tank,yesterday i finished of with tank stand preparations(painting the metal skeleton,sanding the woods to remove drops of paint and applying varnish were i had sanded the old one...)So today i will start the sump setting up,connecting the sump pumps and passing the tubing...

Photos will follow soon...

Posted: 31 Aug 2007, 07:12

by Kostas

Ok,here is what exactly is printed on the ducting pipes:Alfagomma-Italy-Ducting S161 UL94 V2

Do you have any idea on that stuff?

Thank you very much in advance

Posted: 31 Aug 2007, 10:19

by MatsP

Kostas wrote:Ok,here is what exactly is printed on the ducting pipes:Alfagomma-Italy-Ducting S161 UL94 V2

Do you have any idea on that stuff?

Thank you very much in advance

You're not a very good googler, are you?

http://www.alfagomma.net/altro/catzip/A ... NGLESE.pdf

http://www.alfagomma.net/altro/catzip/A ... NGLESE.pdf

According to the above document, the material is PVC. It's not recommended for water use tho'. But I guess is simply that if you use it unsupported for some length, it will simply not take the weight of the water. Rigid pipes are best for water...

--

Mats

Posted: 31 Aug 2007, 15:05

by Kostas

Hi Mats,

Thank you very much for your reply

I did found that document at my search in the morning,but having a quick look i didnt found anywhere the material it is made from...

Now looking again,many pages down,i found that it is made exclusively from pvc

Thank you very veru much!!!!

You made my day!

Ok,so i guess its ok to leave it,right?There it says its recomended uses from the company...Not that it cant be used for water...But of course i guess it wouldnt withstand pressurized water in it...Anyway,if there is nothing toxic in it,then i think it will be fine for that use,right?

Thank you very much in advance

Posted: 31 Aug 2007, 15:08

by MatsP

I would expect it to be safe, yes.

--

Mats

Posted: 31 Aug 2007, 15:17

by Kostas

Thank you very much Mats!

Why you arent sure?

Because i dont understand it very well,what does it mean ''grey plasticized pvc''?Is the tube made exclusively from pvc or is the tube made from another plastic that just encases the pvc reinforcements?

Also it says ''self extinguising''...Is there any chance it has something bad to achieve that?

Thank you very much in advance

Posted: 31 Aug 2007, 15:25

by MatsP

Yes, and hamburgers are made from beef - but there's a difference between going to your local butcher and see him put a piece of prime beef in the mincer to make YOUR burgers and buying the "9c a piece" burgers at the low-price supermarket, which again is somewhate different from what you get at MacDonalds or the local hole-in-the-wall.

PVC in itself is perfectly fine. I'm 99% sure that whatever additives they have are also "ok with water". But all plastic materials have additives that make the material behave in certain ways (softeners to make it bend, anti-UV additives to make it less likely to deteriorate in sunlight, pigments to make it look nice (or dull grey in this case), etc, etc). What makes me quite sure, but not 100%, is that it wouldn't be particularly good to have a bit of condensation in an air-duct that takes with it something that is unhealthy. But on the other hand, that's not the same as being fish or drinking-water safe, right?

--

Mats

Posted: 31 Aug 2007, 15:34

by Kostas

Right...

So,i will stop bothering with this U.T.P.(Unknown Toxicity Pipe

) and go buy something that i am 100% sure its made for drinking water...Just for peace of mind...

Ok,so,having seen the way the overflow is made,what would you suggest me to use as overflow piping?Should i use rigid black drinking water pvc,food grade piping like the one i have,or drinking water flexible piping?

Thank you very much in advance

Posted: 31 Aug 2007, 15:49

by MatsP

Ok, let's first say that I think the current pipe is VERY small risk - but I'm generally carefull about saying things like "that's OK", simply because I do know that whenever you are saying something for sure, someone else proves you wrong - so I'm quite likely overcautios.

I also can't really say what pipes you should or shouldn't use, because although I've seen some pictures, I can't really say exactly what you need - I presume flexible pipes are there for the purpose of being able to remove the overflow housing without dismantling the pipework completely. Rigid pipes tend to mean that you can't trivially remove them once they are installed...

--

Mats